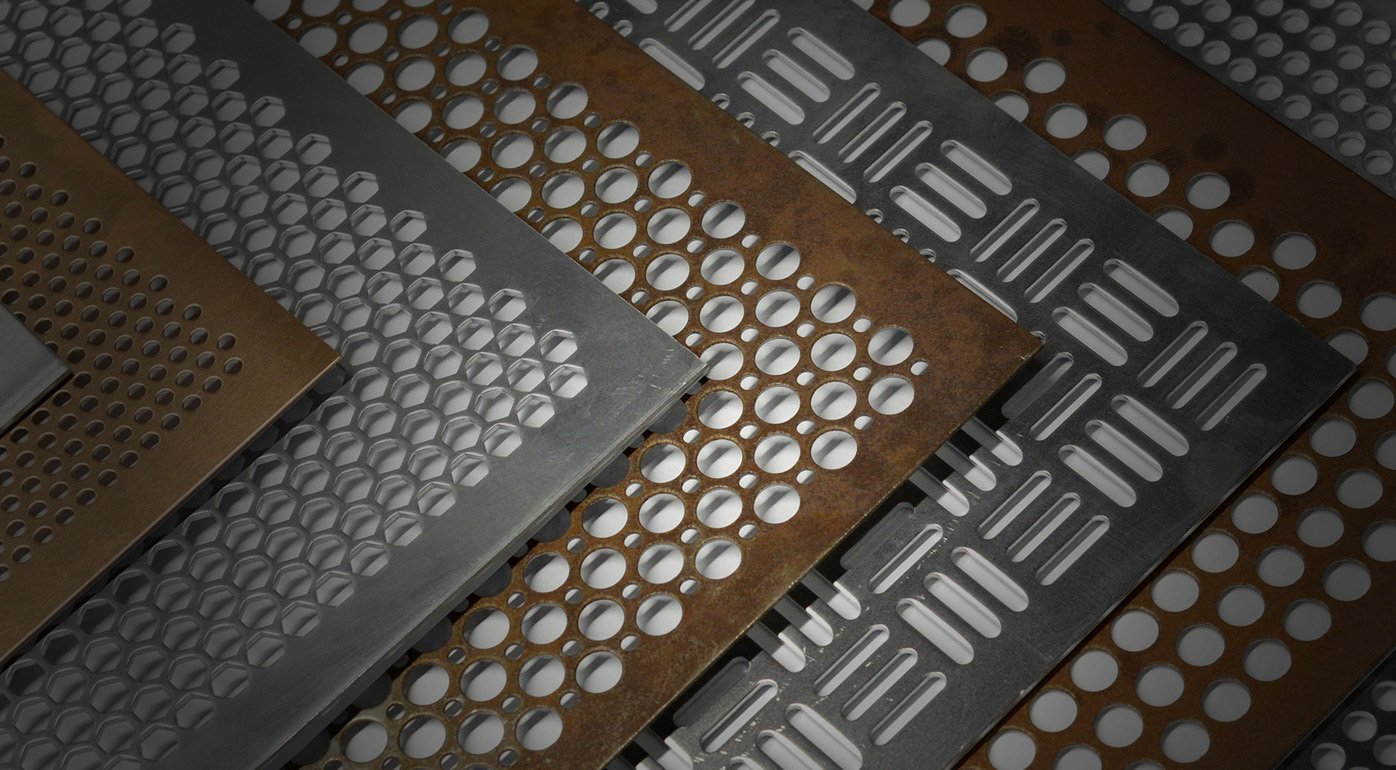

Aluminum Sheet Plate 6061 comes from the most adaptable aluminum alloys. The alloy of choice for all-purpose applications is 6061 aluminum plates. Aluminum, silicon, and magnesium alloy strengthened by precipitation hardening are known as 6061 aluminum plates.

We manufacture aluminum 6061 sheets of medium strength; formability, weldability, machinability, and corrosion resistance are all characteristics of this alloy. In addition to being beneficial in welded structural applications, we utilize 6061 aluminum plates for tooling plates, architectural purposes, transportation equipment, and bridge railing components. We have thick sheets of 6061 aluminum in stock of several measurements that are now in stock and ready to ship.

Description

At Xiaaluplate, we use silicon and magnesium to make 6061 aluminum plates that are of high quality. This type of aluminum is easily machinable, weldable, and formable. In terms of corrosion resistance, it ranks first among heat-treated aluminum in its class. Because of this, people use it in marine settings and heavy-duty buildings.

Our 6061 Aluminum Sheets Manufacturers export affordable and quality products to your doorstep. We have an industry-leading team of exporters and suppliers who ensure quality products at your convenience.

Why Are Aluminum 6061 Plates Best to Use?

This item features a shielding surface coating that prevents corrosion. Additional coatings or we can anodize to increase corrosion resistance. This metal has a conductivity that is 40% that of copper. Electrical fittings and connectors made of it are good for the electrical industry.

Moreover, marine fittings, marine components, fasteners, truck components, hinge pins, magneto parts, frames, and structural components are a few further uses for 6061 Aluminum Sheets grades. It is perfect for heavy-duty buildings because of its favorable weight-to-strength ratio.

This product has excellent welding capabilities, enabling the use of any welding technique. It is possible to anneal it, which will prepare it for straightforward cold working. Stamping, drilling, bending, deep drawing, tapping, cutting, and cold working techniques will suit you best.

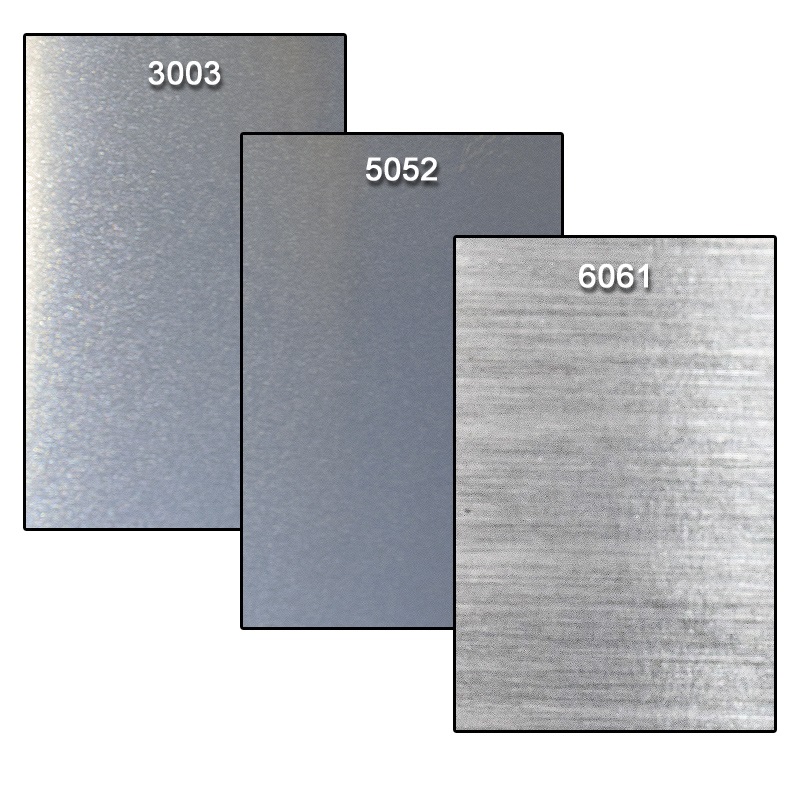

003-H14 Aluminum Sheet – (ASTM B209, QQ-A-250/2) Excellent weldability and formability, with good corrosion resistance makes 3003 Aluminum Sheet a popular and economical choice. 3003 Aluminum Sheet has a smooth, semi-shiny finish and is popular for many applications, including: fuel tanks, food & chemical handling, trailer siding & roofing, etc.

Non-magnetic, Brinell = 40, Tensile = 22,000, Yield = 21,000 (+/-)

5052-H32 Aluminum Sheet – (ASTM B209, QQ-A-250/8) Superior corrosion resistance, good weldability, with excellent formability, makes 5052 Aluminum Sheet a common choice for chemical, marine or saltwater applications. 5052 Aluminum Sheet applications include: tanks, marine hardware, boat hulls, etc.

Non-magnetic, Brinell = 60, Tensile = 33,000, Yield = 28,000 (+/-)

6061-T651 Aluminum Sheet – (ASTM B209, QQ-A-250/11) Offers a combination of increased strength, corrosion resistance, and machinability making it the most widely used aluminum grade. 6061 Aluminum Sheet is heat treatable, resists cracking due to stress, is easy to weld and machine, but limited on formability. 6061 Aluminum Sheet is ideal for structural framing, base plates, gussetts, motorcycle & automotive parts, etc.

Non-magnetic, Brinell = 95, Tensile = 45,000, Yield = 40,000 (+/-)

Available Stock Sizes: 1ft x 1ft, 1ft x 2ft, 1ft x 4ft, 2ft x 2ft, 2ft x 4ft, 4ft x 4ft, 4ft x 8ft, 4ft x 10ft or Cut to Size or Custom Shape.

Ordering Note: Stock sizes may vary +/- 1/8″. Please call if you need specific sizes. Aluminum sheets are bare without PVC, so minor imperfections may be present. Inquire about PVC protective mask for a near blemish free surface.

You Might Be Looking For

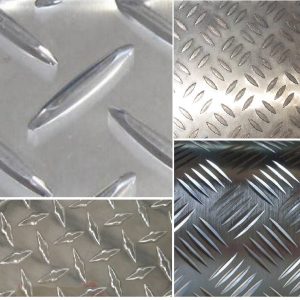

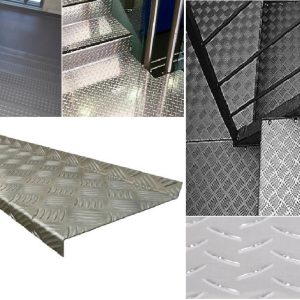

Stucco Embossed Aluminum Sheet

Aluminum Plate – 3003, 5052, 6061