soft forming quality Electro hot dip galvanized steel plate SECC JIS G 3313 Electro-Galvanized Commercial Cold Rolled

Electro Galvanized Steel(EGI) EGI is made in the way of electro galvanizing zinc over cold rolled steel. This product with high corrosion resistance has less coating than GI steel but features even coating thickness, good surface, and coating at a low temperature

SECC steel is electro-galvanized commercial quality cold rolled steel which is basically cold rolled and then coated with zinc in an electro-galvanizing line. SECC is a material grade and designation defined in JIS G 3313 standard. It is a low-cost steel metal grade with improved thermal conduction that is mostly utilized for the casings of computer and other electronic accessories. As a basic Zinc-Coated Carbon Steel it can be enumerated in mild steel which is processed under electro galvanization, unlike the SGCC steel which is processed hot-dip galvanized steel.

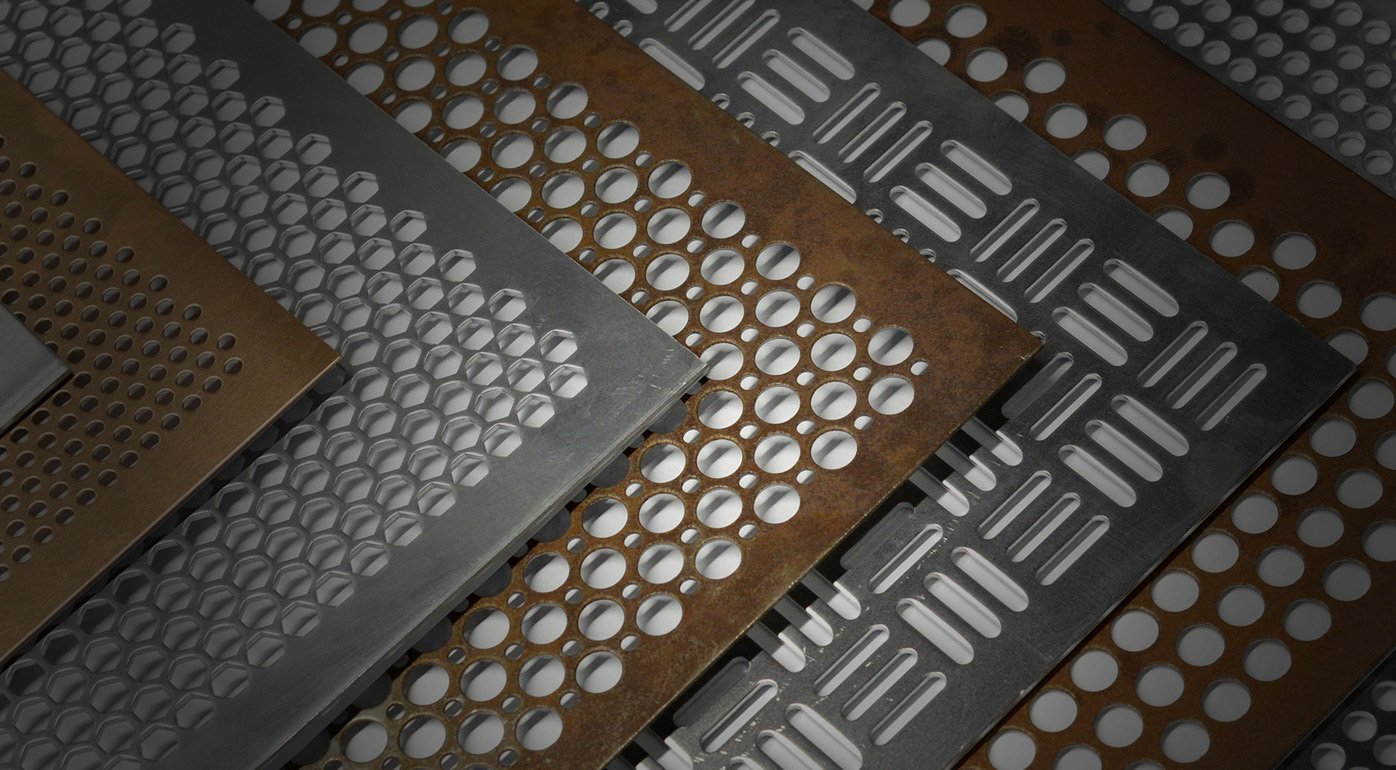

The based metal is actually made up of commercial quality cold rolled steel but the coating is made up of zinc through electro galvanization process unlike the hot-dip galvanized steels. Following forming operations can be performed on this type of steel:

- Pressing

- Blanking

- Shaping

- Lancing

- Piercing

- Notching

- Stamping

However, any specific forming operation should be properly investigated and testing should be performed before the execution.

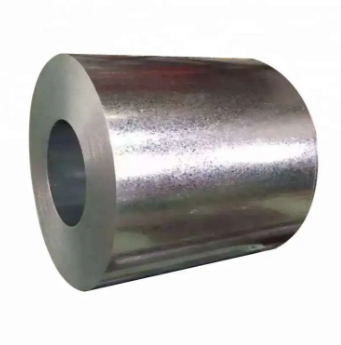

Following are the available forms of SECC steels in the global market:

- Galvanized Coils

- Slit Edge Galvanized Coils

- Cut to Length Galvanized Sheets

Description

SECC is a stamping material, which is coated with a zinc layer on the surface of the cold-rolled sheet. Rust and corrosion-resistant

SECC electrogalvanized plates and strips are featured with good erosion-resistant, high surface quality(O5 plate surface are available) and excellent processing and coating performances. They can be used to manufacture inside an outside automotive plates , structural parts and reinforcements

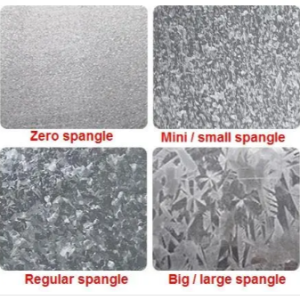

The electro galvanization process is an industrial process which is used to coat base steel with the layer of zing by electroplating. The zinc coating obtained through this process protects the base steel from rust and corrosion. Moreover, the zinc coating achieved through electroplating process is highly accurate and precise if the coating thickness is considered. There are two types of electrolytes that are used for electro galvanization i.e. alkaline and acidic electrolytes.

Nominal thickness: 0.30mm~2.0mm, nominal width: 800mm~1830mm

(Note: nominal thickness of a plate/strip is sum of base plate thickness and coating thickness.)

When a material grade is specified as electro-galvanized steel, it simply refers it has been subjected to an electro galvanization process by which galvanization is performed. Through this process, a coating of zinc is applied on the surface of the steel. Zinc protects the steel from rusting and other issues. Zinc coating increases the life of base steel. Since the coating is done through electrolysis, therefore, it is said as electro-galvanized steel

- The mechanical and process performances of pure zinc coated plates/strips must comply with the stipulations of those of relevant base plates. The base plate grade is SPCC、SPCD、SPCE, and the corresponding base plate standards is Q/BQB 402-2003.

- Among the mechanical performances of Zn-Ni alloy coated plates/strips, breakage percent elongation is allowed to be lowered by 2 units against that of relevant base plates, r is allowed to be lowered by 0.2 against that of relevant base plates and other mechanical and process performances shall comply with the stipulations of those of relevant base plates