Description

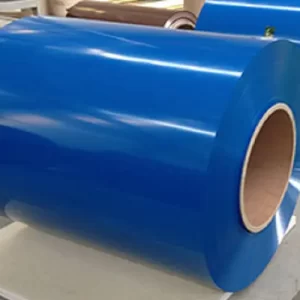

PPGI is pre-painted galvanised iron, also known as pre-coated steel, coil coated steel, color coated steel etc., typically with a hot dip zinc coated steel substrate. The term is an extension of GI which is a traditional abbreviation for Galvanized Iron.

Using Hot Dip Galvanized Steel Coil as the substrate, PPGI is made by first going through surface pretreatment, then the coating of one or more layers of liquid coating by roll coating, and finally baking and cooling. The coatings used including polyester, silicon modified polyester, high-durability, corrosion-resistance and formability

PPGI is short for pre-painted galvanized steel, while PPGL is short for pre-painted galvalume steel. As the name suggests, PPGI uses galvanized sheets (with a layer of zinc coating) as base metal. While PPGL is with galvalume sheet as substrate, which is coated with 55% aluminum, 43.3% zinc, and 1.6% silicon. This is the main difference between PPGI and PPGL, which will further influence their features and applications.

PPGL stands for pre-painted galvalume steel, which is a kind of color-coated steel with GL as substrate. It combines the strength of steel with excellent anti-corrosion of Zn-Al coating. The galvalume coating is made of 55% aluminum, 43.4% zinc, and 1.6% silicon

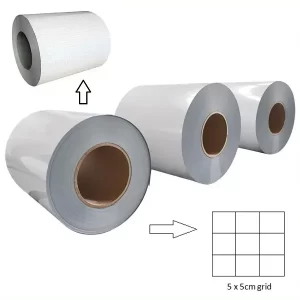

| Name | Prepainted Galvanized Steel Coils |

| Type of substrate |

Hot dip galvanized, Galvalume, Electro galvanized, Cold rolled steel, Aluminium |

| Thickness | 0.13-1.5mm |

| Tolerance | Thickness: ±0.01mm |

| Width | 600-1250mm ( Normal:1250, 1200,1000, 914, 900, 762, 750mm) |

| Top Paint | 15-35 micron(Normal:10-20mic) |

| Back paint | 7-35 micron(Normal:5-7mic) |

| Coil weight | 3-5 tons or as your requirement. |

| ID | 508/610 mm |

| Grade | SGCC/DX51D+Z, DX52D+Z, SGCD/DX53D+Z,SGCE/DX54D+Z, SGCH |

| Coating type | Top paint: PE, SMP, HDP, PVDF, PU |

| Functions: Decorative, Machinability, Weather resistance, Scrath resistance, Stain resistance, Chemical resistance, Adhesion resistance |

|

| Primer paint: Polyurethane, Epoxy, PE | |

| Functions:Machinability,Corrosive resistance,Adhesion, Scrath resistance |

|

| Back paint: Epoxy, Modified polyester | |

| Functions: Scrath resistance, Bending adhesion, Corrosive resistance | |

| Packing | Standard export package .Plastic film in the first layer,second layer is Kraft paper. Third layer is galvanized sheet. |

| Application | Building industry, structural use, roofing, commercial use, household appliance, industry facilities, office buildings |

Galvalume Steel Sheet_Aluminum-Zinc Alloy Coated Steel Sheets (GL) are galvanized steel sheets with both zinc and aluminum, and is the ideal combination of anti-corrosion and alkali-resistance of zinc, and the durability, heat-resistance, and acid-resistance of aluminum.