Titanium sheet has found favour in industries such as aerospace, power generation, petrochemical and automotive. Pure titanium sheet metal and titanium alloy plate and sheets to ASTM B265, ASME SB265 standards and other regional standards. Titanium sheet is often used as a heat barrier because titanium stops the heat and does not transfer to the rest of the assembly. Titanium plate and sheet have ballistic properties making it great for driver protection in racing.

Description

Titanium sheet has found favour in industries such as aerospace, power generation, petrochemical and automotive. Offering extra-high strength and low weight, the alloys high tensile strength combined with low heat transfer make it highly suitable for a range of engineering applications. Titanium sheet is an excellent material for high-volume production of components by stamping or waterjet cutting.

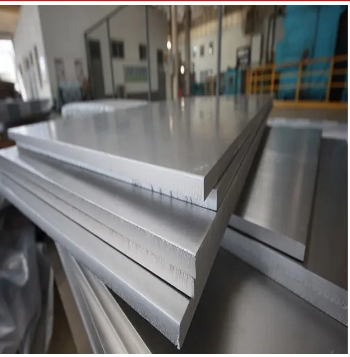

Titanium sheet and plate can be supplied to a number of different surface finishes. The importance of the surface finish is largely determined by the application and closeness to finished state as typically surfaces of products maybe be completed after final fabrication. The common supply state is an annealed mill finish.

We offer various surface finishes dependent on size and supply conditions. The differing types of surface finishes are:

- Milled

- Polished

- Pickling (descaled)

- Brushed

- Blasted – Shot / Sand

Finishing and supply states which result in different surfaces are not explicitly defined in standards and as such are largely dependent on the individual mill and agreements outside of any standards. The ASTM B600 standard is the key standard in providing a guide to the descaling and cleaning of titanium and titanium alloys but does not define the gloss, colour or roughness that a surface should have.

Material: CP titanium, Titanium alloy

Grade: Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 etc

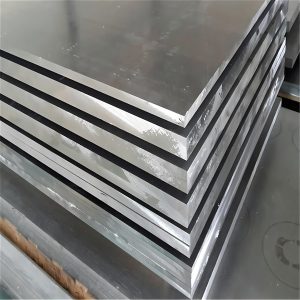

Size: Thickness: 0.3~5mm, Width: 400~3000mm, Length: ≤6000mm

Standard: ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 etc

Status: Hot Rolled (R), Cold Rolled(Y), Annealed (M), Solution treatment (ST)

Titanium sheet and plate are commonly used in manufacturing today, with the most popular grades being 2 and 5.

Grade 2 Titanium

Grade 2 is the commercially pure titanium used in most of the chemical processing plants and is cold formable. Grade 2 plate and sheet can have ultimate tensile strength at and above 40,000 psi.

Grade 5 Titanium

Grade 5 is the aerospace grade and is not cold formable, so it is used more often when no forming is needed. Grade 5 aerospace alloy will have ultimate tensile strength at and above 120,000 psi.

Our company provides titanium coil and titanium sheet. We have plenty of titanium sheets in stock. That can be cut in different sizes according to the customer’s needs, greatly shorten the time of delivery.

We mainly provide pure titanium sheet of Gr1, Gr2, Gr4 grades; For titanium alloy sheet, We mainly provide Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 and other grades.

Application

Used in the production of heat exchanger, tower, reaction kettle.

Used in the production of metal composite material.

Used in electrolytic copper industry.

Used to produce titanium mesh.

|

UNS No. |

UNS No. |

||||

|

Gr1 |

UNS R50250 |

CP-Ti |

Gr11 |

UNS R52250 |

Ti-0.15Pd |

|

Gr2 |

UNS R50400 |

CP-Ti |

Gr12 |

UNS R53400 |

Ti-0.3Mo-0.8Ni |

|

Gr4 |

UNS R50700 |

CP-Ti |

Gr16 |

UNS R52402 |

Ti-0.05Pd |

|

Gr7 |

UNS R52400 |

Ti-0.20Pd |

Gr23 |

UNS R56407 |

Ti-6Al-4V ELI |

|

Gr9 |

UNS R56320 |

Ti-3Al-2.5V |

|||

Specification

|

Grade |

Status |

Specification |

||

|

Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr12,Gr16,Gr23 |

Hot Rolled(R) Cold Rolled(Y) Annealed(M) Solution treatment(ST) |

Thickness(mm) |

Width(mm) |

Length(mm) |

|

0.3~5.0 |

400~3000 |

1000~6000 |

||

Chemical composition

|

Grade |

Chemical composition, weight percent (%) |

||||||||||||

|

C ≤ |

O ≤ |

N ≤ |

H ≤ |

Fe ≤ |

Al |

V |

Pd |

Ru |

Ni |

Mo |

Other Elements Max. each |

Other Elements Max. total |

|

|

Gr1 |

0.08 |

0.18 |

0.03 |

0.015 |

0.20 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr2 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr4 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr5 |

0.08 |

0.20 |

0.05 |

0.015 |

0.40 |

5.5~6.75 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr7 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

0.12~0.25 |

— |

0.12~0.25 |

— |

0.1 |

0.4 |

|

Gr9 |

0.08 |

0.15 |

0.03 |

0.015 |

0.25 |

2.5~3.5 |

2.0~3.0 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr11 |

0.08 |

0.18 |

0.03 |

0.15 |

0.2 |

— |

— |

0.12~0.25 |

— |

— |

— |

0.1 |

0.4 |

|

Gr12 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

— |

— |

0.6~ 0.9 |

0.2~0.4 |

0.1 |

0.4 |

|

Gr16 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

0.04~0.08 |

— |

— |

— |

0.1 |

0.4 |

|

Gr23 |

0.08 |

0.13 |

0.03 |

0.125 |

0.25 |

5.5~6.5 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.1 |

Physical properties

|

Grade |

Physical properties |

||||||||

|

Tensile strength Min |

Yield strength (0.2%, offset) |

Elongation in 50mm Min (%) |

Bend Test(Radius of Mandrel) |

||||||

|

ksi |

MPa |

min |

max |

<1.8mm In thickness |

1.8mm~4.57mm In thickness |

||||

|

ksi |

MPa |

ksi |

MPa |

||||||

|

Gr1 |

35 |

240 |

20 |

138 |

45 |

310 |

24 |

1.5T |

2T |

|

Gr2 |

50 |

345 |

40 |

275 |

65 |

450 |

20 |

2T |

2.5T |

|

Gr4 |

80 |

550 |

70 |

483 |

95 |

655 |

15 |

2.5T |

3T |

|

Gr5 |

130 |

895 |

120 |

828 |

— |

— |

10 |

4.5T |

5T |

|

Gr7 |

50 |

345 |

40 |

275 |

65 |

450 |

20 |

2T |

2.5T |

|

Gr9 |

90 |

620 |

70 |

483 |

— |

— |

15 |

2.5T |

3T |

|

Gr11 |

35 |

240 |

20 |

138 |

45 |

310 |

24 |

1.5T |

2T |

|

Gr12 |

70 |

483 |

50 |

345 |

— |

— |

18 |

2T |

2.5T |

|

Gr16 |

50 |

345 |

40 |

275 |

65 |

450 |

20 |

2T |

2.5T |

|

Gr23 |

120 |

828 |

110 |

759 |

— |

— |

10 |

4.5T |

5T |

Tolerance (mm)

|

Thickness |

Width tolerance |

|

|

400~1000 |

>1000 |

|

|

0.3~0.5 |

±0.05 |

±0.05 |

|

0.5~0.8 |

±0.07 |

±0.07 |

|

0.8~1.1 |

±0.09 |

±0.09 |

|

1.1~1.5 |

±0.11 |

±0.13 |

|

1.5~2.0 |

±0.15 |

±0.16 |

|

2.0~3.0 |

±0.18 |

±0.20 |

|

3.0~4.0 |

±0.22 |

±0.22 |

|

4.0~5.0 |

±0.35 |

±0.35 |

Testing

Chemical composition test

Physical properties test

Appearance defects inspection

Ultrasonic flaw detection

Eddy current testing

Packaging

In order to avoid the titanium sheets have any collision in transit or damage, usually wrapped with pearl cotton (expandable polyethylene), and then packed into wooden case for delivery.