Alloy 625 nickel pipe is made from a nickel-chromium-molybdenum alloy with an addition of niobium. High strength and toughness from cryogenic temperatures to 1800°F. Good oxidation resistance, exceptional fatigue strength, and good resistance to many corrosives.

Austenitic: 304/L/H/N, 316/L/H/N/Ti, 321/H,309/H,310S, 347/H, 317/L, 904L

Duplex steel: 31803, 32205, 32750, 32760

Nickel alloy: UNS N10001, N10665, N10675, N06455, N06022, N10276, N06200, N06035, N06030,N06635, N10003, N06002, R30188, N06230, R30556, UNS N06660, N06601, N06617, N07718, N07750, N08800, N08811, N08825, N09925, N08926, UNS N04400, N05500

Precipitation-hardnening steels: 254SMO / 331254, 17-4PH,17-7PH, 15-7PH

Nickel: N4 / UNS N02201, N6 / UNS N02200

Description

Inconel alloys have nickel as their base element, which improves the performance of Inconel 625 Seamless Pipe at elevated temperatures. Inconel 625 is an alloy that also performs well at lower temperatures. A change in temperature causes alloyed pipes to expand or contract.

China made Nickel Alloy N06625 Welded Pipe & ASTM B444 Inconel 625 Pipes With good mechanical strength at elevated temperatures, alloy 625 is known as a high temperature alloy. Inconel alloys have nickel as their base element, which improves the performance of Inconel 625 Seamless Pipe at elevated temperatures.

Alloy 625 is a nickel based alloy that offers flexible weldability and incredible corrosion resistance that is suitable for many different industrial applications. It has been specifically engineered to be used in some of the world’s most demanding conditions. The alloy is used in a variety of fields such as chemical processing, aerospace engineering, marine engineering, pollution control and even nuclear reactors. Its versatility has led it to become a popular alloy that is particularly useful in (but not limited to) the following applications:

- Engine thrust-reversers

- Aircraft ducting systems

- Turbine shroud rings

- Bellows and expansion joints

- Gaskets and damper seals

- Jet engine exhaust systems

- Valve seats and components

- Furnace muffles

- Seawater components

- Flare stacks

- Seawater processing

- Chemical processing equipment

- Steam piping

Alloy 625 (UNS N06625/W.Nr. 2.4856) Chemical Composition

| Weight % | Ni | Cr | Mo | Nb + Ta | Fe | Ti | C | Mn | Si | S | P | Al | Co |

| Alloy 625 | 58.0 min | 20 – 23 | 8 -10 | 3.15 -4.15 | 5.0 max | 0.40 max | 0.10 max | 0.50 max | 0.50 max | 0.15 max | 0.15 max | 0.40 max | 1.0 max |

Alloy 625 (UNS N06625/W.Nr. 2.4856) Mechanical Properties

| Material Form and Condition | Tensile Strength MPa | Yield Strength (0.2% Offset) MPa | Elongation 4D(%) | Hardness HB | |||

| Ksi | MPa | Ksi | MPa | ||||

| Alloy 625 Bar | Annealed | 120 | 827 | 60 | 414 | 30 | ≤ 287 HB |

| Alloy 625 Sheet | Annealed | 120 | 827 | 60 | 414 | 30 | 145-240 |

| Alloy 625 Tube Seamless and Welded |

Annealed | 120 | 827 | 60 | 414 | 35 | – |

Alloy 625 provides the perfect mix of corrosion resistance and strength. When oxidation is a concern, it provides good resistance up to temperatures of 1093°C. Due to the nickel content, it’s virtually immune to corrosion by chloride as well, which is why it’s used in many seawater applications and also chemical processing. If you need to use Alloy 625 pipes with hazardous materials or extreme temperatures, it can withstand the punishment and retain its shape, giving you confidence in its ability.

Alloy 625 is also incredibly resistant to extreme temperatures. Compared to most varieties of steel, alloy 625 does not lose tensile strength at extreme temperatures, making it one of the most temperature-tolerant materials that can be used in industrial applications such as heat treatments thanks to its ability to hold its shape despite the temperatures. This is what makes it such a suitable material for jet engines, but it’s not just heat that Alloy 625 can withstand. Even in environments where the alloy is exposed to extremely cold temperatures, Alloy 625 strengthens itself faster than stainless steel to become tougher and easier to work with.

Despite all of these incredible advantages, Alloy 625 still manages to have good welding capabilities and can be shaped and formed to your needs. In short, if you’re looking for a material that can withstand extreme temperatures both hot and cold, is still flexible enough to be shaped to your needs and can even resist corrosion in seawater, then Alloy 625 is the perfect material for your needs. It might be an expensive material, but as one of the toughest metals available in the industry and the countless applications for its use, it’s worth the cost

We manufacture Inconel 625 seamless pipe & tube strictly according to ASTM B444. Inconel 625 has high strength, which makes the cold rolling process of seamless pipe & tube more difficult. We have a complete seamless pipe & tube production line, which can fully guarantee the quality of pipes. In addition, we do a complete hydrostatic test on all pipes. If you have requirements for the grain size of the material, we can also meet your requirements.

Available Products and Specifications

INCONEL alloy is designated as UNS N06625, Werkstoff Number 2.4856 and ISO NW6625 and is listed in NACE MR-01-75. It is available in all standard mill forms including rod, bar, wire, and wire rod, plate, sheet, strip, shapes, tubular products, and forging stock.

Rod, Bar, Wire and Forging Stock – ASTM B 446/ASME SB 446 (Rod & Bar), ASTM B 564/ASME SB 564 (Forgings), SAE/AMS 5666 (Bar, Forgings, & Rings), SAE/AMS 5837 (Wire), ISO 9723 (Rod & Bar), ISO 9724 (Wire), ISO 9725 (Forgings), VdTÜV 499 (Rod & Bar), BS 3076NA21 (Rod & Bar), EN 10095 (Rod, Bar, & Sections), DIN 17752 (Rod & Bar), ASME Code Case 1935 (Rod, Bar, & Forgings), DIN 17754 (forgings), DIN 17753 (Wire).

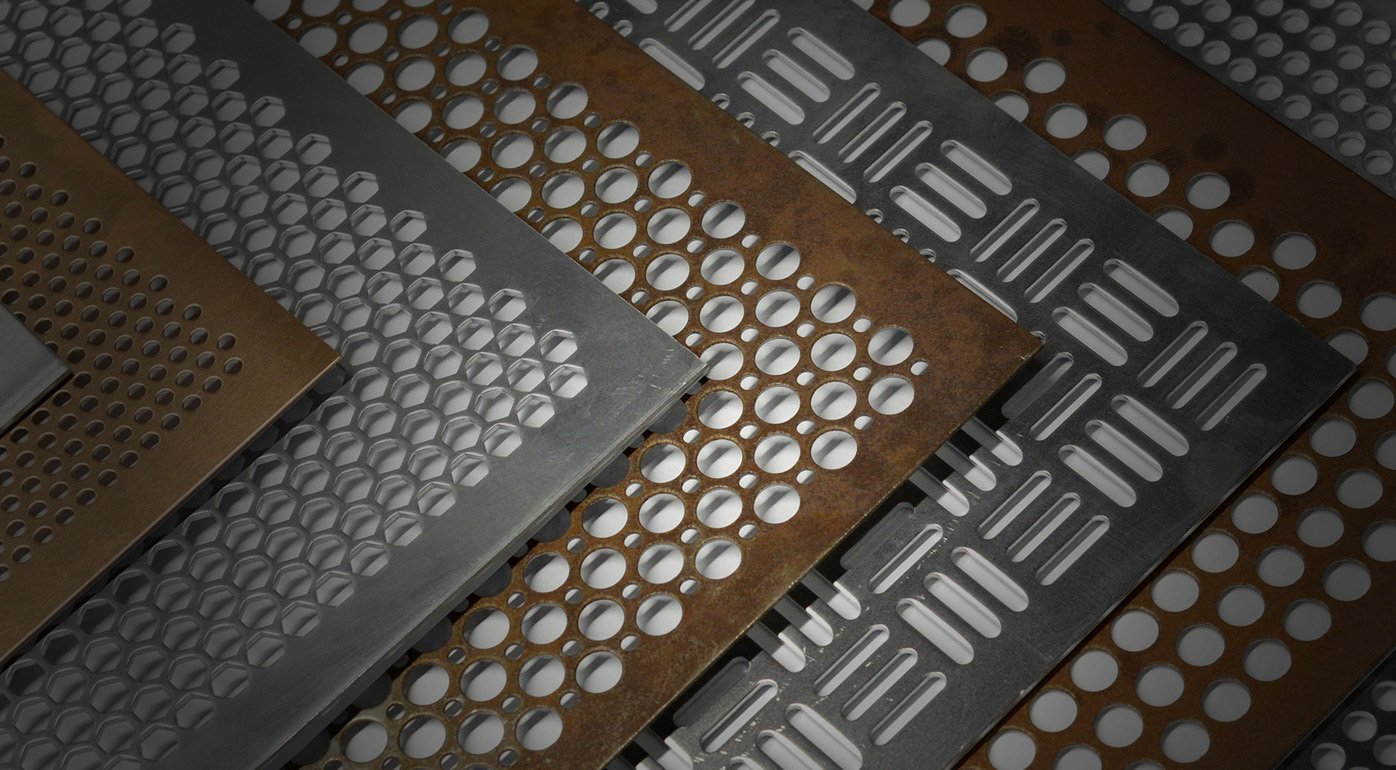

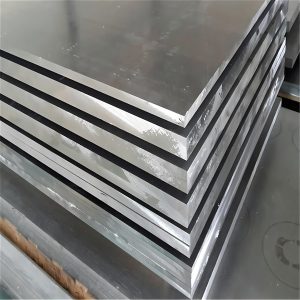

Plate, Sheet and Strip – ASTM B 443/ASTM SB 443 (Plate, Sheet & Strip), SAE/AMS 5599 & 5869 & MAM 5599 (Plate, Sheet & Strip), ISO 6208 (Plate, Sheet & Strip), VdTÜV 499 (Plate, Sheet & Strip), BS 3072NA21 (Plate & Sheet), EN 10095 (Plate, Sheet & Strip), DIN 17750 (Plate, Sheet & Strip), ASME Code Case 1935.

Pipe & Tube – ASTM B 444/B 829 & ASME SB 444/SB 829 (Seamless Pipe & Tube), ASTM B704/B 751 & ASME SB 704/SB 751 (Welded Tube), ASTM B705/B 775 & ASME SB 705/SB 775 (Welded Pipe), ISO 6207 (Tube), SAE/AMS 5581 (Seamless & Welded Tube), VdTÜV 499 (Tube), BS 3074NA21 (Seamless Pipe & Tube), DIN 17751 (Tube), ASME Code Case 1935.

Other Product Forms – ASTM B 366/ASME SB 366 (Fittings), ISO 4955A (Heat Resisting Steels & Alloys), DIN 17744 (Chemical composition of all product forms).