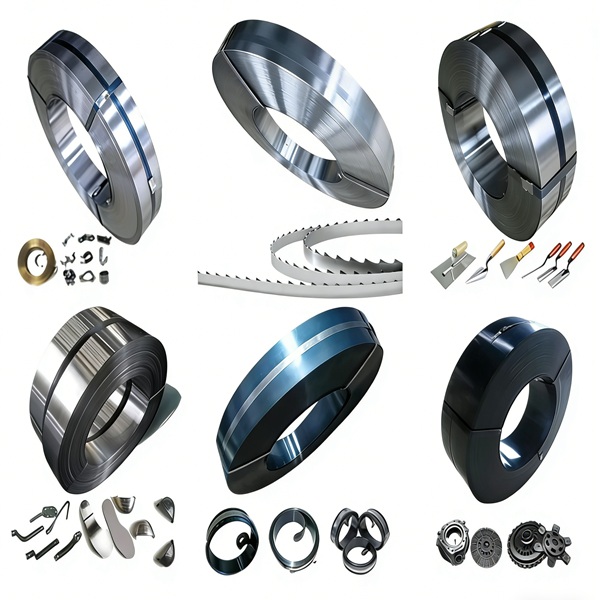

Spring Steel Strip Grade 65Mn, C75, and C100s are three premium high carbon steels engineered for superior strength and elasticity. 65Mn (0.62-0.70% C) is a versatile manganese-alloyed steel known for its excellent toughness and wear resistance, ideal for general springs and tools. C75 (0.70-0.80% C) offers a balanced profile of high elasticity and good formability for demanding mechanical components. For the utmost hardness and fatigue strength, C100S (0.95-1.05% C) is the top choice, especially for critical applications like valve springs.

Description

65Mn Spring steel strip is a medium carbon Manganese (Mn) alloy spring steel widely used in China. Its name indicates an average carbon content of 0.65% and a higher manganese content (1.00-1.30%). After proper heat treatment, it offers excellent elasticity, strength, and wear resistance.

| Spring Steel Strip Parameter | Specification / Value |

|---|---|

| Material Standard | GB/T 1222 (China) / AISI 1566 (similar int’l grade) |

| Key Characteristics | High elasticity, good hardenability, moderate price |

| Primary Applications | Flat/round springs, clutch discs, brake springs, wear-resistant parts |

1. 65Mn Spring Steel Strip Chemical Composition (GB/T 1222)

| Element | C (Carbon) | Mn (Manganese) | Si (Silicon) | P (Phosphorus) | S (Sulfur) |

|---|---|---|---|---|---|

| Content (%) | 0.62 – 0.70 | 0.90 – 1.20 | 0.17 – 0.37 | ≤ 0.035 | ≤ 0.035 |

2. Mechanical Properties (After Heat Treatment)

| Property | Typical Value |

|---|---|

| Tensile Strength (Rm) | ≥ 980 MPa |

| Yield Strength (Rp0.2) | ≥ 785 MPa |

| Elongation (A) | ≥ 8% |

| Hardness (HRC) | 38 – 60 (depends on tempering) |

Heat Treatment Process

The performance of 65Mn is fully realized through quenching and tempering:

-

Quenching: Heat to 830°C ± 10°C, then cool rapidly in oil. This results in a very hard but brittle martensitic structure.

-

Tempering: Reheat the quenched steel to a temperature between 370°C – 500°C, then cool. This step reduces brittleness and achieves the desired combination of strength and elasticity.

-

Higher tempering temperatures (e.g., 450-500°C) yield lower hardness (HRC 38-45) but higher elasticity, ideal for springs.

-

Lower tempering temperatures (e.g., 370-420°C) yield higher hardness (HRC 45-50+) and better wear resistance, suitable for tools and wear parts.

-

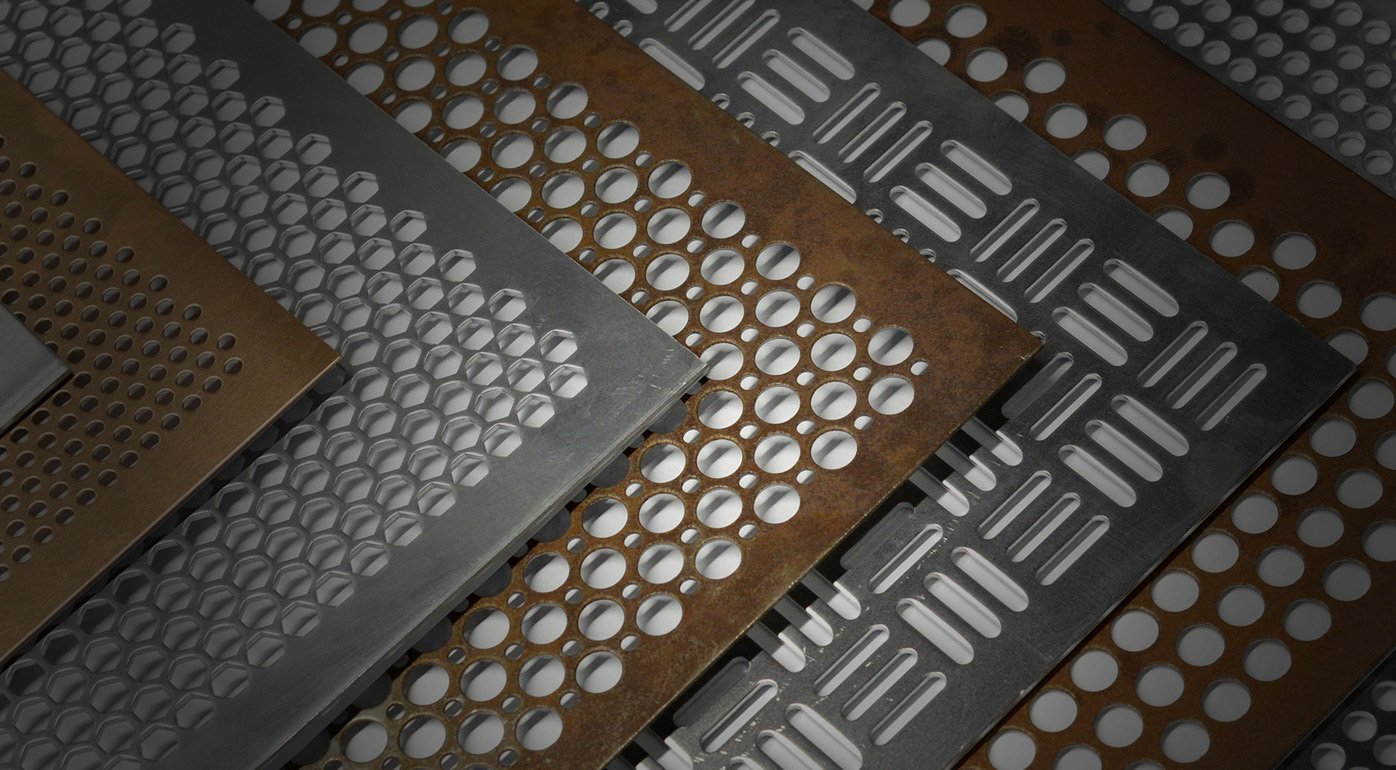

Spring Steel Strip Supply Conditions & Applications

-

Cold-Rolled Hardened Strip: Supplied in a hard state (high strength), suitable for directly stamping small, low-precision springs.

-

Annealed (Soft) Strip: Supplied in a soft state for ease of machining or forming before final heat treatment.

-

Typical End Uses: Seat springs, saw blades, clutch springs, brake springs, spring washers, agricultural knives, and guide rails.

C100S is a high-carbon chromium spring steel that conforms to German standard EN10132-4:2000. It is commonly used to manufacture high-strength, high-elasticity springs and elastic elements.

C100S Spring steel strip is a high-carbon steel, also known as 1.1274 or AISI 1095, prized for its high tensile strength, hardness, and elasticity after heat treatment.

C100S Steel Strip coil is used in applications requiring high elasticity and strength, such as various types of springs, feeler gauges, and precision cutting tools.

CS100 spring steel strip is not corrosion-resistant and requires proper care to prevent rust.

SAE1075 or CK75 contains 0.7-0.8% carbon, 0.15-0.35% silicon, 0.6-0.9% manganese, and 0.03% phosphorus and sulphur. It has a tensile strength of 1230-1340 MPa, yield strength of 1130-1240 MPa, and a hardness of 57-63 HRC.

CK75 spring steel strip has better hardenability, the critical hardenable diameter in oil can reach 100~150mm.

CK75 or C75 is Suitable for making very large springs, such as stacked leaf springs on bulldozers, large coil springs and large torsion springs on ships.

CK75 spring steel is a high-carbon steel material. Its chemical composition mainly includes carbon (C) content between 0.70-0.80%, silicon (Si) content between 0.10-0.35%, and manganese (Mn) content between 0.60-0.80%.

Between 0.90%, the contents of phosphorus (P) and sulfur (S) are less than 0.025% respectively.

CK75 spring steel strip has good elasticity and toughness and is often used to manufacture springs, blades, saw blades, knives and other parts and tools that require high strength and wear resistance.

Core Specifications Comparison

| Feature | C75 (and similar grades: C75S, CK75) | C100S (and similar grades: CK101, 1.1274) |

|---|---|---|

| Common Standards/Grades | C75, C75S, CK75, AISI 1075 (similar U.S. grade) | C100S, CK101, Mat. No. 1.1274 (German DIN/EU EN) |

| Chemical Composition (Core Difference) | High Carbon Steel: C ~ 0.70–0.80%, Mn ~ 0.60–0.90% | Very High Carbon Steel: C ~ 0.95–1.05%, Mn ~ 0.30–0.60% |

| Typical Mechanical Properties | High elasticity, good overall performance. Hardness after quenching & tempering can reach ~56 HRC. |

Extremely high hardness, elastic limit, and wear resistance; relatively lower toughness. |

| Common Supply Conditions | Annealed (soft, for forming) or hard condition (HV 150-650). | Usually supplied annealed or hardened & tempered, typically harder than C75 in the same condition. |

| Primary Applications | General-purpose springs (saw blades, automotive leaf springs, tools), high-stress mechanical parts. | High-stress valve springs, precision wear-resistant parts (e.g., high-end blades,Precision mechanical parts). |

| Key Related Standards | Can refer to ASTM A684 (for 1075), DIN EN 10132-4. | EN 10132-4:2000 (Standard for cold rolled narrow steel strip) is a primary standard. |

C75 is a high-carbon, general-purpose spring steel, while C100S is a very high-carbon steel designed for the most demanding application