Titanium plate are widely used in the aviation field, such as for manufacturing aircraft structural parts, engine parts and aviation titanium alloy plates.

In addition, in the medical field, titanium alloys are also used to manufacture artificial joints, dental implants, and medical devices due to their good biocompatibility and mechanical properties.

Description

Titanium plate is an alloy plate based on titanium and added with other elements.

Titanium alloy has the advantages of high thermal strength, high strength, and good corrosion resistance, but it also has the disadvantages of being expensive.

Depending on the type and content of alloying elements, titanium alloys can be divided into various types to meet the needs of different application scenarios.

The production process of titanium plate includes smelting, casting, rolling and other processes.

It is necessary to strictly control the chemical composition and impurity content of the raw materials, as well as the process parameters during the smelting, casting and rolling processes to ensure the performance and quality of the plates.

Grade: Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 , Ti6242, Ti6246 etc

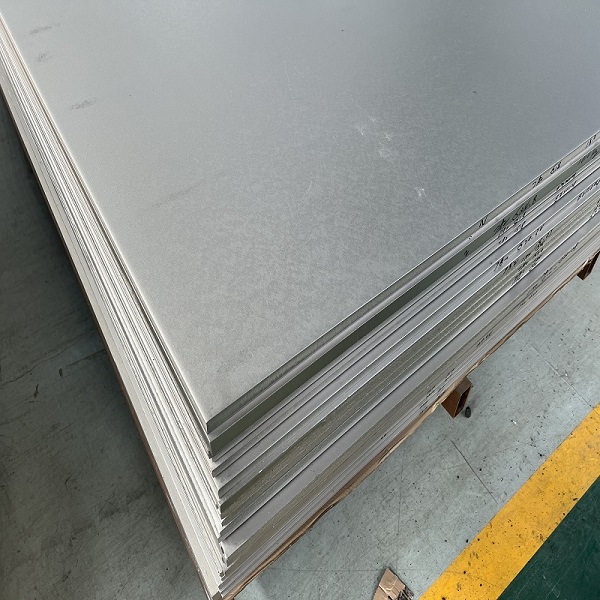

Titanium Plate Size: Thickness: 0.3~150mm, Width: 400~3000mm, Length: ≤6000mm

Titanium bar: Dia 6-600mm, Length ≤6000mm

Titanium Disc: Dia 80-2800mm

Standard: ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 etc

Status: Hot Rolled (R), Cold Rolled(Y), Annealed (M), Solution treatment (ST)

Our company provides titanium coil and titanium plate. We have plenty of titanium sheets in stock. That can be cut in different sizes according to the customer’s needs, greatly shorten the time of delivery.

We mainly provide pure titanium plate of Gr1, Gr2, Gr4 grades; For titanium alloy sheet, We mainly provide Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 and other grades.

Application

Used in the production of heat exchanger, tower, reaction kettle.

Used in the production of metal composite material.

Used in electrolytic copper industry.

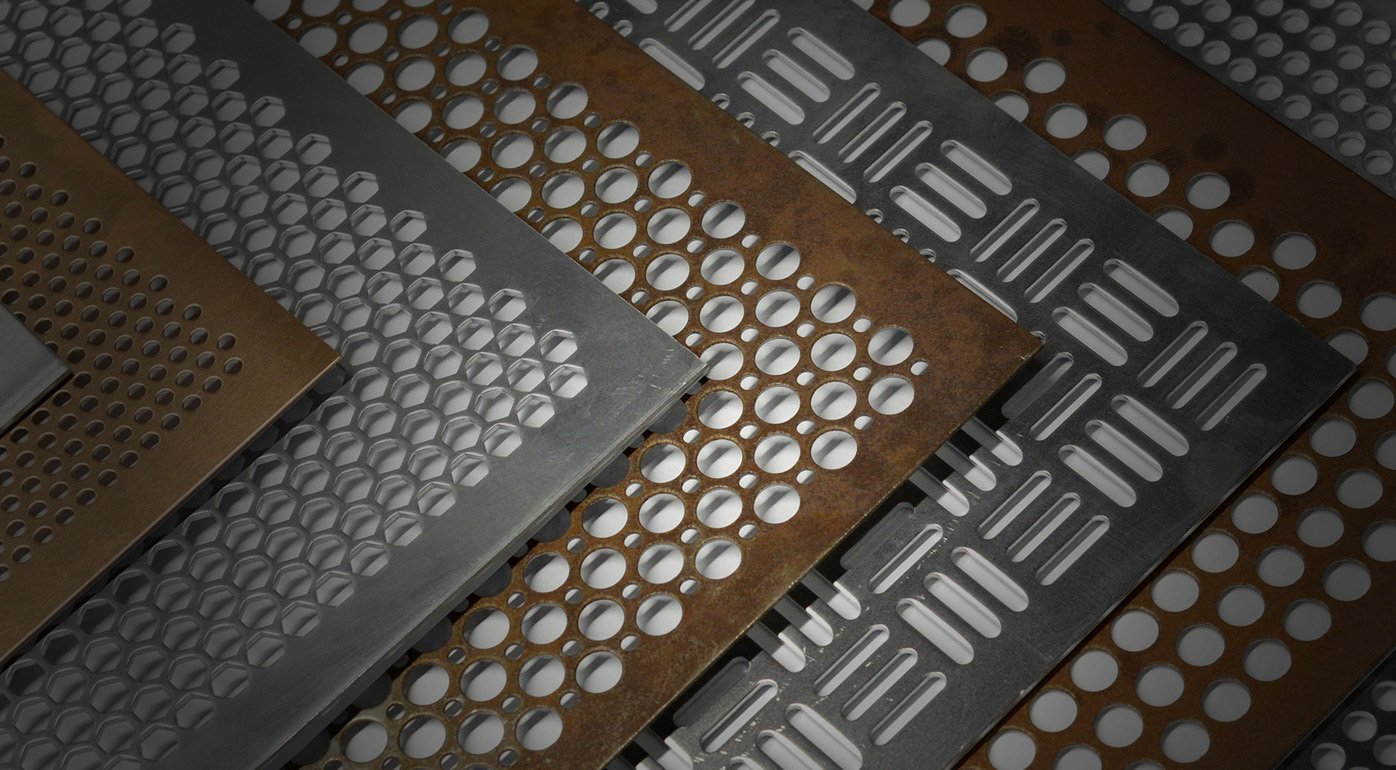

Used to produce titanium mesh.

|

UNS No. |

|

UNS No. |

|||

|

Gr1 |

UNS R50250 |

CP-Ti |

Gr11 |

UNS R52250 |

Ti-0.15Pd |

|

Gr2 |

UNS R50400 |

CP-Ti |

Gr12 |

UNS R53400 |

Ti-0.3Mo-0.8Ni |

|

Gr4 |

UNS R50700 |

CP-Ti |

Gr16 |

UNS R52402 |

Ti-0.05Pd |

|

Gr7 |

UNS R52400 |

Ti-0.20Pd |

Gr23 |

UNS R56407 |

Ti-6Al-4V ELI |

|

Gr9 |

UNS R56320 |

Ti-3Al-2.5V |

|

|

|

Specification

|

Grade |

Status |

Specification |

||

|

Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr12,Gr16,Gr23 |

Hot Rolled(R) Cold Rolled(Y) Annealed(M) Solution treatment(ST) |

Thickness(mm) |

Width(mm) |

Length(mm) |

|

0.3~5.0 |

400~3000 |

1000~6000 |

||

Chemical composition

|

Grade |

Chemical composition, weight percent (%) |

||||||||||||

|

C ≤ |

O ≤ |

N ≤ |

H ≤ |

Fe ≤ |

Al |

V |

Pd |

Ru |

Ni |

Mo |

Other Elements Max. each |

Other Elements Max. total |

|

|

Gr1 |

0.08 |

0.18 |

0.03 |

0.015 |

0.20 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr2 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr4 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr5 |

0.08 |

0.20 |

0.05 |

0.015 |

0.40 |

5.5~6.75 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr7 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

0.12~0.25 |

— |

0.12~0.25 |

— |

0.1 |

0.4 |

|

Gr9 |

0.08 |

0.15 |

0.03 |

0.015 |

0.25 |

2.5~3.5 |

2.0~3.0 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr11 |

0.08 |

0.18 |

0.03 |

0.15 |

0.2 |

— |

— |

0.12~0.25 |

— |

— |

— |

0.1 |

0.4 |

|

Gr12 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

— |

— |

0.6~ 0.9 |

0.2~0.4 |

0.1 |

0.4 |

|

Gr16 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

0.04~0.08 |

— |

— |

— |

0.1 |

0.4 |

|

Gr23 |

0.08 |

0.13 |

0.03 |

0.125 |

0.25 |

5.5~6.5 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.1 |

Physical properties

|

Grade |

Physical properties |

||||||||

|

Tensile strength Min |

Yield strength (0.2%, offset) |

Elongation in 50mm Min (%) |

Bend Test(Radius of Mandrel) |

||||||

|

ksi |

MPa |

min |

max |

<1.8mm In thickness |

1.8mm~4.57mm In thickness |

||||

|

ksi |

MPa |

ksi |

MPa |

||||||

|

Gr1 |

35 |

240 |

20 |

138 |

45 |

310 |

24 |

1.5T |

2T |

|

Gr2 |

50 |

345 |

40 |

275 |

65 |

450 |

20 |

2T |

2.5T |

|

Gr4 |

80 |

550 |

70 |

483 |

95 |

655 |

15 |

2.5T |

3T |

|

Gr5 |

130 |

895 |

120 |

828 |

— |

— |

10 |

4.5T |

5T |

|

Gr7 |

50 |

345 |

40 |

275 |

65 |

450 |

20 |

2T |

2.5T |

|

Gr9 |

90 |

620 |

70 |

483 |

— |

— |

15 |

2.5T |

3T |

|

Gr11 |

35 |

240 |

20 |

138 |

45 |

310 |

24 |

1.5T |

2T |

|

Gr12 |

70 |

483 |

50 |

345 |

— |

— |

18 |

2T |

2.5T |

|

Gr16 |

50 |

345 |

40 |

275 |

65 |

450 |

20 |

2T |

2.5T |

|

Gr23 |

120 |

828 |

110 |

759 |

— |

— |

10 |

4.5T |

5T |

What are the important applications of titanium alloy plates in the aerospace field?

Titanium plate are widely used in the aerospace field, mainly due to their high strength, corrosion resistance, low temperature resistance, and good high temperature resistance and corrosion resistance.

Here are some specific application examples:

Aircraft and engine manufacturing: Titanium plate are widely used in the manufacturing of aircraft structural parts, such as girders and partitions and other structural frame parts.

Titanium plate is also an ideal material for key engine components, such as titanium fans, compressor discs and blades, engine covers and exhaust devices, to improve engine performance and reliability.

Spacecraft manufacturing: In the field of spacecraft, titanium alloy plates are used to manufacture various pressure vessels, fuel tanks, fasteners, instrument straps, frames and rocket casings due to their high strength and corrosion resistance.

On artificial satellites, lunar modules, manned spacecraft and space shuttles, titanium alloy plate welding parts play a key role.

Thermal insulation materials and shell manufacturing: Titanium alloys have excellent thermal conductivity and high temperature stability and can be used to manufacture thermal insulation materials for aerospace vehicles, effectively reducing the impact of high temperatures during the spacecraft’s entry into the atmosphere and re-entry.

At the same time, the titanium alloy shell can protect the equipment and systems inside the spacecraft, providing good structural strength and air tightness.

Space probe manufacturing: Titanium alloy plates can provide sufficient strength and rigidity to protect the probe from vibrations and vibrations in the space environment.

Its low magnetism and high optical transparency also provide unique advantages in electromagnetic interference and optical sensors.