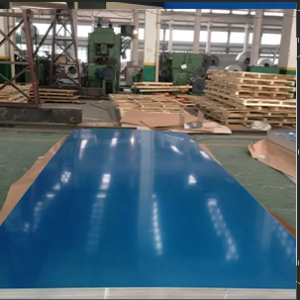

Mill Finish Aluminum Sheet Circle 1060 1070 1100 3003 Aluminum Plate For Cookware

Aluminum circle 1050 1060 1070 3003 etc is mainly used in making cookware, like non-stick pan, pressure cooker, hardware and pressure cooker and so on. Aluminum circle disc is the most widely used deep drawing products, High tensile strength, good ductility, Anodized quality and deep drawing quality which is suitable for cookware as well.

1. Excellent elongation and tensile strength;

2. Processing performance is good, stamping, stretch forming high performance;

3. Gas welding, hydrogen welding, resistance welding and brazing;

4. High plasticity, conductivity and thermal conductivity;

5. Easy to take all kinds of pressure processing and extension, bending;

Aluminum Circle or aluminium disc is a circular flat product obtained by circular sawing or shearing like the diameter over 700 mm, or by blanking for diameter less than 700 mm of a flat rolled product with a uniform thickness over 0.5 mm. Its stock is usually the cold rolled sheet in coil or rectangular sheet in small size, and both DC and CC materials are available upon request. It is subsequently formed or drawn for applications of kitchenware and containers.

Description

What is the difference between cold rolled aluminum sheet and hot rolled ?

Compared with hot rolling, the main feature of cold rolling is that thinner sheets and strips can be obtained.

Usually, the thickness of hot rolled sheet is 6-8 mm. The minimum thickness is 2.5mm-3.0mm. Due to the large temperature drop in the hot rolling process, it is difficult to continue rolling to a thinner thickness, while cold rolling can easily continue to thin the rolling stock.

Usually, cold rolling mills can roll down to 0.5-4.5 mm. Advanced cold rolling mills can roll thin or thick foils with a thickness of 0.1-0.2 mm. Cold rolling can produce products with precise dimensions, uniform thickness, good smoothness and surface gloss, good structural properties and high surface quality.

There are four main differences between hot-rolled and cold-rolled aluminum sheet:

1. Different uses: cold-rolled aluminum sheets are mostly used for molds, and hot-rolled aluminum sheets are suitable for stamping and drawing.

2. Different performance: hot-rolled aluminum plate has good surface quality, strong mechanical properties and ductility, and good oxidation effect. At the same time, the processed aluminum disc is generally processed from aluminum plate, which is naturally also affected by the performance of aluminum plate;

3. The supply of raw materials is different: the difference between the two is the supply of billets. The hot-rolled billets are vertically cast into billets—heated—rolled into coils for cold rolling, while the cold-rolled billets are cast-rolled coils—continuous casting and continuous casting. rolling;

4. The production process is different: cold rolling is processed by a casting machine into a cast roll (8mm thickness) and processed by a cold rolling machine, while hot rolling is heated by an aluminum ingot (400-500mm thickness), which is heated by a high temperature. Rolled by hot rolling mill;

The aluminum disc circle is made from very high-quality raw material that ensures high durability for users which is why the disc provided by us is high in demand for making cookware products. We, as one of the leading aluminium disc circle suppliers, continuously strive to provide the highest quality aluminum products to customers.

Our aluminum discs are wildly used for producing cookware, utensil, pizza pan, pressure cooker, bakeware, road sign, traffic sign, and so on.

Since it is 99.5% pure aluminum, it has no break or orange peel problems when you spinning or deep drawing. We can produce both CC and DC aluminum discs

China aluminum discs supplier RAYIWELL MFG / RUIYI strictly control and test the alloy, temper and performance of the aluminum coil to ensure the accuracy and diversity of the aluminum circle provided. The surface performance of the aluminum discs is good, and it is guaranteed that there are no obvious scratches, oil stains, oxidation, black spots, etc. When the thickness of aluminum circle discs is higher than 1.0 mm, the edges of the finished aluminum circle product are guaranteed to be neat and free of burrs. The introduction of advanced and efficient production equipment improves the production efficiency of the aluminum disc and the utilization rate of materials, effectively shortens the production cycle, and provides customers with real-time convenience

We are Aluminum Circle Suppliers, aluminium disc manufacturers, and exporter of Aluminum Circles. We provide supreme quality of heavy gauge circles with thicknesses between 0.3mm – 4mm and diameter ranging between 3.94″ – 38.5, which would meet your needs for making cookware such as pots, pans, fryers etc.

With us, one of the top Aluminum circle suppliers, here’s what you can expect on average from our sources abroad:

- Alloy: 1050, 1060, 1070, 1100, 3002, 3003, 3004, 5052A, 5052, 5754, 6061

- Hardness: O, H12, H14, H16, H18

- Thickness: 0.012″ – 0.15″ (0.3mm – 4mm)

- Diameter: 3.94″ – 38.5″ (100mm -980mm)

- Surface: Polished, Bright, Anodized

- Usage: Suitable for making pots, pans, pizza trays, pie pans, cake pans, covers, kettles, basins, fryers, light reflectors

- Stamping: Materials include: steel, galvanized steel, aluminum, aluminum alloy and other metals

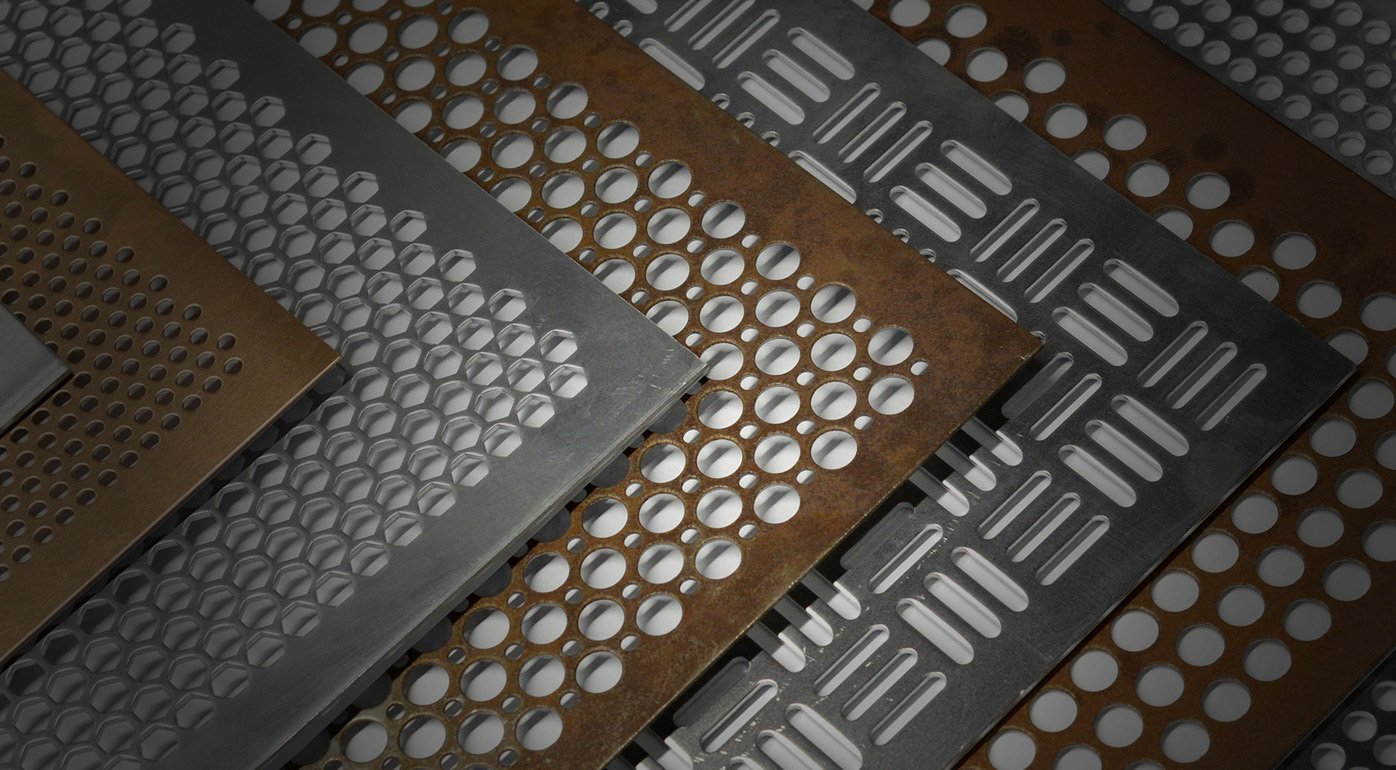

aluminum stair tread sheet, Aluminum tread Brite plate,Aluminum checker plate manufacturers, Perforated aluminum sheet china,Diamond sheet manufacturers, Aluminum tread plate manufacturers, Aluminium sheet factory, aluminium plate metal, aluminum sheet circlesum Sheet Circle / 1060 1070 1100 3003 Aluminum Plate For Cookware