Before more towards aluminum chequer plate, you must know about Aluminium sheets. They, also recognized as aluminum plates, are elemental raw-form aluminum being pressed and rolled into panel form below high pressure. Various checkered aluminum plate types are available in the metal supplier market.

Aluminum sheet manufacturers characteristically manufactured sheetings to be very thin and lightweight, sturdy enough to provide extreme versatility alongside characteristic ease of installation and maintenance. Moreover, it boasts numerous other unique and advantageous properties that create it very widely organized today across an enormous variety of agricultural, industrial, home DIY, and manufacturing or production applications.

A variety of additional coatings applied to aluminum sheets can help make a long-lasting material for use in outdoor settings or various challenging environments, like for exterior cladding. The tremendously lightweight nature of thin sheet aluminum makes it perfect for drinks cans, food containers, and other ordinary products suitable for high-volume storage, transportation, and retail.

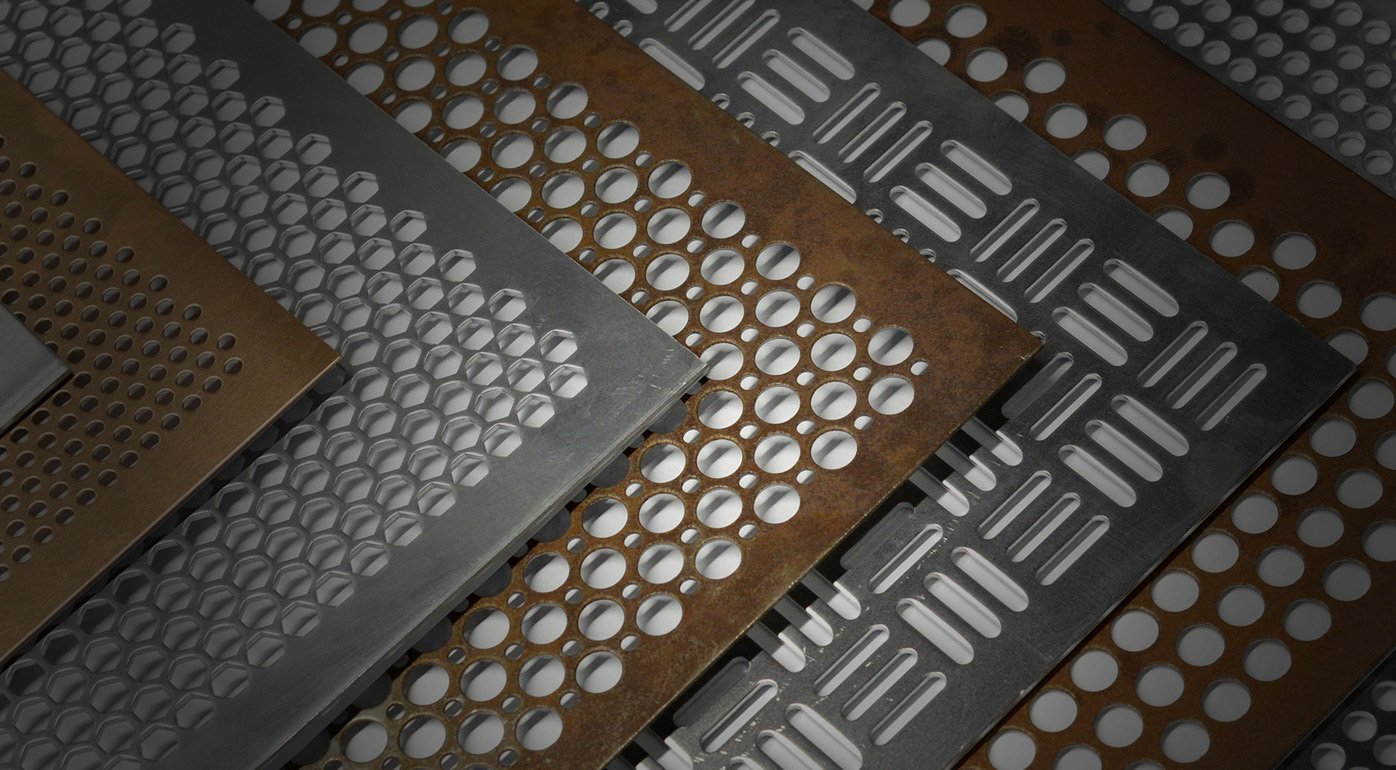

Surface measurements and thickness are the primary factors to consider while looking at options to purchase aluminum sheeting. However, the overall surface area is the first essential characteristic you want to believe in planning a trade using sheet metal. The various material surfaces available will also play a significant part in selecting the perfect aluminum sheet for your requirements and intended applications.

For example, Anodised aluminum sheeting can provide robust protection against corrosion and a more aesthetically attractive outer face. However, the aluminum sheet manufacturers coat or protect raw or unfinished aluminum sheets in various ways when initial forming and fabrication are complete. Appropriate for use with fastener and plate fixings and welding purposes, people view aluminum plate as exceptionally user-friendly sheet metal, containing high formability and easy to cut to size for various applications.

It is commonly cut to 1mm-2mm thickness, and at the weight, you can form quickly by hand or with smaller handheld tools. However, thicker aluminum plates may need either manually operated forming machines or more industrial-type inflated presses or brakes to work into the preferred shape.

Chequer Aluminum Plate:

People use chequer plates in decorative, architectural applications, and shipbuilding – as it is anti-corrosive and does not need painting, so it is low maintenance. Chequer aluminum plate is a very versatile material with various uses.

The checkered aluminum plate has good forming; it is easy to practice and has good weldability. This steel is also an excellent slip-resistant material. People use it as a protective aluminum sheet for some designs. However, a chequer aluminum plate is a perfect option for situations demanding high hygiene levels. The aluminum plate is easy to clean as dirt. You can brush or wipe it off and can remove the stain easily. Chequer aluminum plate is also easy to replace when necessary – with little or no effort required.

People use aluminum Chequer Plate in the following applications:

- Corner guard for walls- interior decoration

- Stair treads

- Tread decking

- Floors for elevators

- Door kicking plate

- Use as decoration in modern cars – floors

- Commercial use – shopping centers with high footfall