A form of aluminum plate known as “aluminum diamond plate” has a diamond shape pattern imprinted into it. Although this pattern frequently works for aesthetic reasons, it can also be utilized to create a non-slip surface.

Diamonds may be cheaply and quickly bonded to sheets of lightweight aluminum. It provides the superior strength and durability of this material by design. Garage walls, fitness centers, mechanical rooms, cafeterias, and storage facilities. Moreover, vehicle washes, grow facilities, and a number of other applications. These frequently make use of this embossed diamond plate. The Xiaoxian Ruiyi Commercial Trade Co., is the diamond plate sheet that is most in demand.

Cut Aluminum

Why Cutting Of Aluminum Diamond Plate Is Significant?

From truck toolboxes to beautiful flooring, aluminum diamond plate is a popular material for a number of applications. Depending on the purpose, it comes in a variety of thicknesses. Because aluminum diamond plate is a tougher material. The diamonds might cause the blade to wander, cutting aluminum diamond plate is different from cutting other types of sheet metal.

You’ll need a steady hand and a sharp carbide-tipped blade to cut aluminum diamond plates. While you can use a jigsaw or circular saw, a table saw will provide the smoothest cut. Make sure the circular saw blade works for cutting aluminum if you’re using one. Half the thickness of the aluminum diamond plate should be the blade depth setting.

Process for Cutting Aluminum: Hints and Techniques

Keep in mind this advice when cutting aluminum to make your job much simpler.

Working Woodworking Tools

You can use some of your premium wood-cutting tools to cut aluminum since aluminum is one of the softer metals.

Apply Lubrication

Metal-cutting lubricants can aid in chip and swarf removal as well as help to lessen chatter and irregularities during the cut. The most popular lubricant for aluminum is WD-40, however, water and other lubricants. It can be metal-cutting wax, and can function effectively to keep blades from clogging.

Better Blades Have a Smaller Diameter

Smaller diameter blades typically provide cleaner, more precise cuts because less runout arises from their smaller diameter, and a smoother cut is what results.

Clamp The Work Object

A steady workpiece enables a better cut, and clamping your workpiece offers it stability. Clamping also increases safety by reducing the possibility of something flying off the saw and injuring the operator.

Wear Safety Gear

When cutting aluminum or any other material, always use sufficient safety gear, such as safety glasses or goggles and hearing protection. Additionally, full-face shields may be wise.

Utilize The Proper Hand Tools

To complete commercial or DIY work, craftsmen use equipment, including chisels, angle grinders, tin snips, and shears. Have the appropriate hand tools to go along with your saws or machine tools, whatever you prefer. Read this whole guide to have an idea for China Aluminum Tread Plate and how you can do it perfectly.

What Tool Do You Use To Cut Aluminum Sheet?

Brass and aluminum are two common examples of soft metals. It doesn’t cost much money to create those materials as a result. A good bimetallic blade ought to be functional. The material of the blade (or the cutting edge or teeth) must be tougher than the object being cut.

The jigsaw blade turns on with the click of a trigger. Gently but firmly, the blade should be driven into the metal. Make sure you follow the pattern or line while allowing the blade to perform its job. The blade will wear out more quickly and become brittle if you try to drive it through the metal.

It is affordable to buy a hammer and chisel, compound snip, or hacksaw. Metal snips, also known as hand shears, can cut sheets along curves and straight lines, but when used to cut within an aluminum sheet, they deform both edges.

Compared to plate or foil, sheet aluminum is a thinner but thicker metal. In big fabrication metal shops, industrial cutting tools like punch presses and plasma cutters are frequently available. You can cut Aluminum sheets using plasma or oxy-hydrogen torches in smaller sheet metal shops. As long as they are exact, hand tools can be used on thin aluminum sheets. Metal snips or hand shears can cut aluminum sheets in both straight and zig zag lines. But when they are cut inside, they deform both edges. The material doesn’t deform but stays flat for a considerable amount of time during jigsaw. Aluminum Tread Plate Manufacturers are the top dealer of all kinds of metal and metalworking supplies.

Hacksaw

An effective instrument for cutting a smaller piece of aluminum is a hacksaw. It works well for cutting pipe and bar, but it also works well for cutting sheet aluminum into shorter lengths. Fortunately, if those don’t work out or if they deteriorate quickly over time, there are different blades available.

CNC device

Cutting aluminum sheet metal or bar stock into smaller, more manageable pieces is best using these techniques. For more intricate work, high-speed CNC machine tools are among the best solutions. You can use CNC lathes and mills to produce whole production runs of identical parts by turning thick aluminum chunks into finished products.

How To Cut An Aluminum Diamond?

Use a permanent marker to draw your cut line on the aluminum diamond plate’s surface. You should put the aluminum diamond plate on a sturdy work surface. You need to fix up the noose if it’s necessary. Use a steady, uniform motion to cut along the defined line. Slow down if the blade starts to wander, and be careful not to push it. To keep the blade from binding, support the off-cuts as you go by using a scrap piece of wood. After you’ve completed cutting, unclamp the aluminum diamond plate and use a file or abrasive pad to remove any burrs.

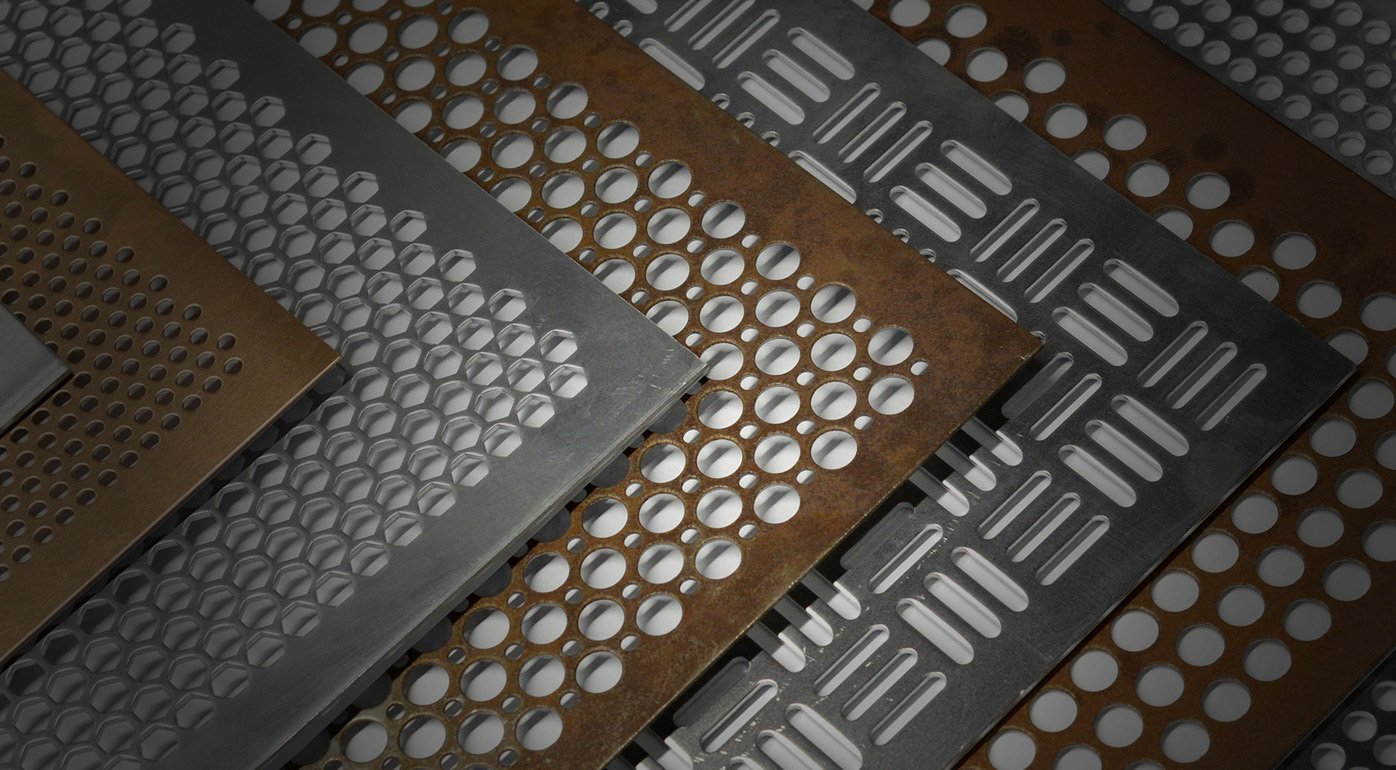

An aluminum sheet with diamonds stamped or embossed on it is an aluminum diamond plate. Due to its anti-slip and aesthetically pleasing texture, this type of plate works well in dance floors, wall panels, countertops, floor mats, and toolboxes. In addition to those in trucks, trailers, and other vehicles, it can also work for steps and floor beds. Four easy steps can be used to cut the aluminum diamond plate into small, usable pieces.

Get in touch with Aluminum checker plate manufacturers, they can provide affordable aluminum plates affordably.