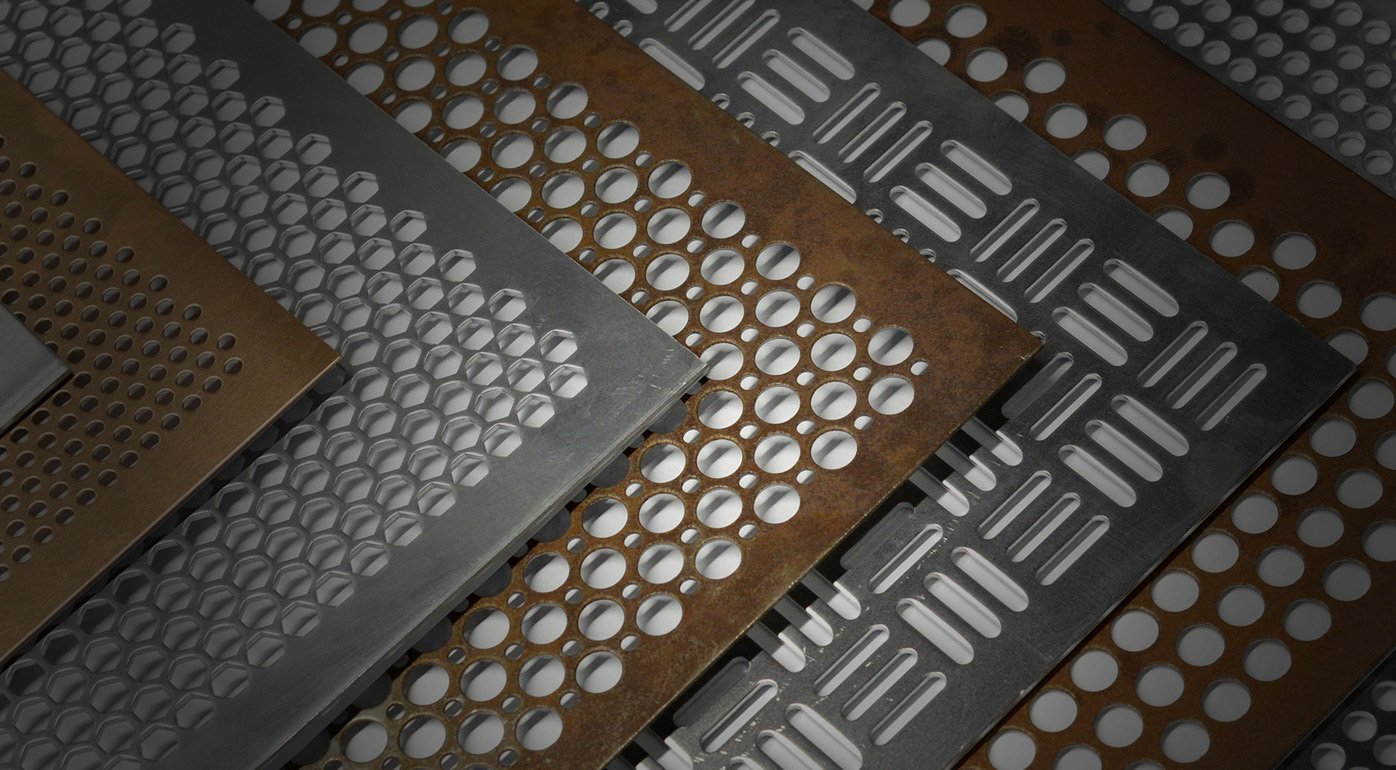

Choosing the right materials for your project is absolutely essential to ensure that there are no problems with end result. All metal types are not the same. Choosing the correct one depends on the metal will be used. To better understand perforated metals and their advantages, read on below.

Perforated Metals

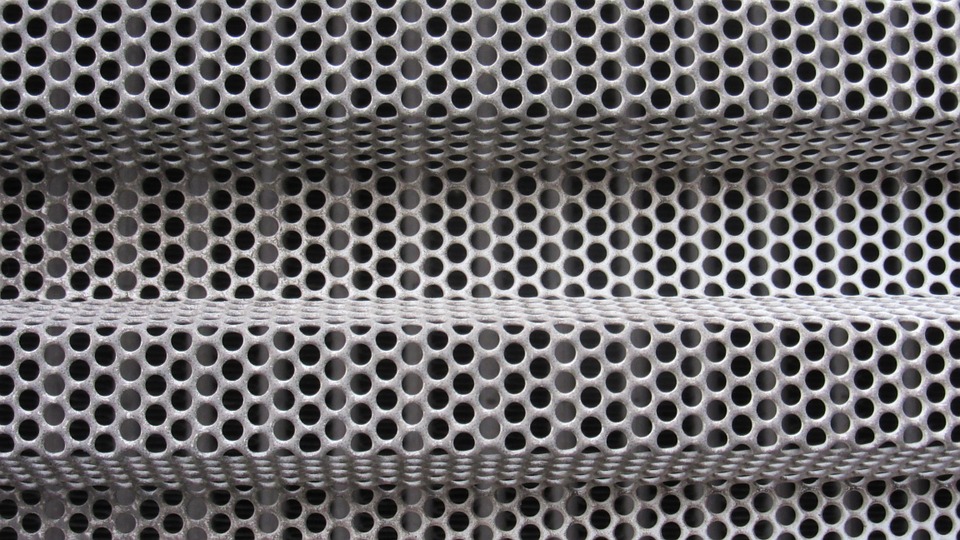

Perforated metal is dependable and strong. Different coatings can be applied to upgrade appearance and enhance life span. Perforated metal can be utilized in a variety of ways, for example, HVAC air diffusers, acoustical boards for noise control, decorative purposes and channel media or support in water filtration. Usually favored for applications requiring light and sound control.

Perforated Steel

Perforated steel is more suited for indoor applications because of its weakness to erosion, however covering with a material, for example, Tnemec can improve the material’s resilience.

One of the key advantages of steel is its quality and capacity to withstand outrageous temperatures, both hot and chilly. It is a pliant material, in spite of the fact that not to the degree of aluminum. As far as extensive scale projects that require perforated materials are concerned, steel is a brilliant and cost effective alternative.

Perforated Aluminum

For outdoor purposes, perforated aluminum is a phenomenal choice. This is in huge part because of aluminum’s capacity to withstand corrosion. It doesn’t compromise on aesthetics and structural integrity even after exposure to rain and various chemicals.

Thus, perforated aluminum sheet is a fantastic choice for applications that include exposure to extraordinarily cold weather, as it gets stronger at below zero temperatures. It’s worth noting though that it does loose some of its strength after exposure to temperatures above 400 degrees Fahrenheit.

Another quality of perforated aluminum is its being low in weight when compared to other metals, especially steel and copper, making the material less demanding to install with fewer attachments points required.

Perforated Copper

Regarding quality, copper is a standout among other metals for its potential for decorative and practical uses. Compared to steel and numerous other metals, copper is a more pliable material. Its sturdiness can be enhanced when combined with other metals and materials.

Copper is preferred over other metals for its longevity and resistance to corrosion. Despite the fact that copper does oxidize and rust, the rust balances out subsequent to turning brown and in the end, green. A few metals, (for example, zinc) added to copper to improve its quality can decrease its corrosion resistance, so it is critical to know the application with a specific end goal to identify the correct balance. For bigger ventures, perforated copper has a tendency to be more costly than other metals.

Perforated Stainless Steel

Stainless steel is a standout among the most well-known choices for perforated metals since it consolidates quality with a high level of resistance to corrosion. It’s made with at least 10 percent chromium that gives it resistance to corrosion up and down its surface.

It additionally has the novel nature of withstanding scratches and scraped areas since its chromium oxide film will repair itself when it comes in to contact with oxygen.

Depending on the type of stainless steel chosen, it can be resistant to different kinds of chemicals and fluids, for example, salt water, which makes it perfect for applications in waterfront locales. It’s also utilized for indoor and outdoor decorative purposes in view of its aesthetics.

Stay tuned to to Xiaaluplate for more interesting blogs, news and articles.