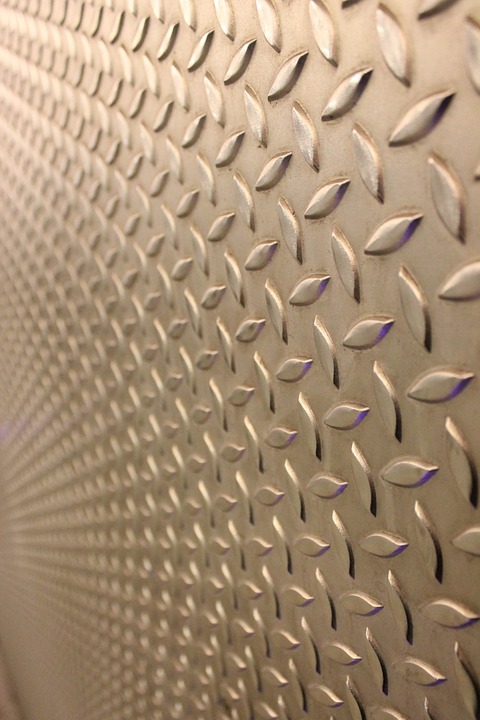

The aluminum diamond plate is one of the most expensive, yet a contemporary material which is used in massive industrial applications.

This product is used in a variety of things including; platforms, air conditioners, cars, table legs, handle, packaging pipes screen skeleton, a variety of hanging beams, cable trough and cover, chair, and to name a few.

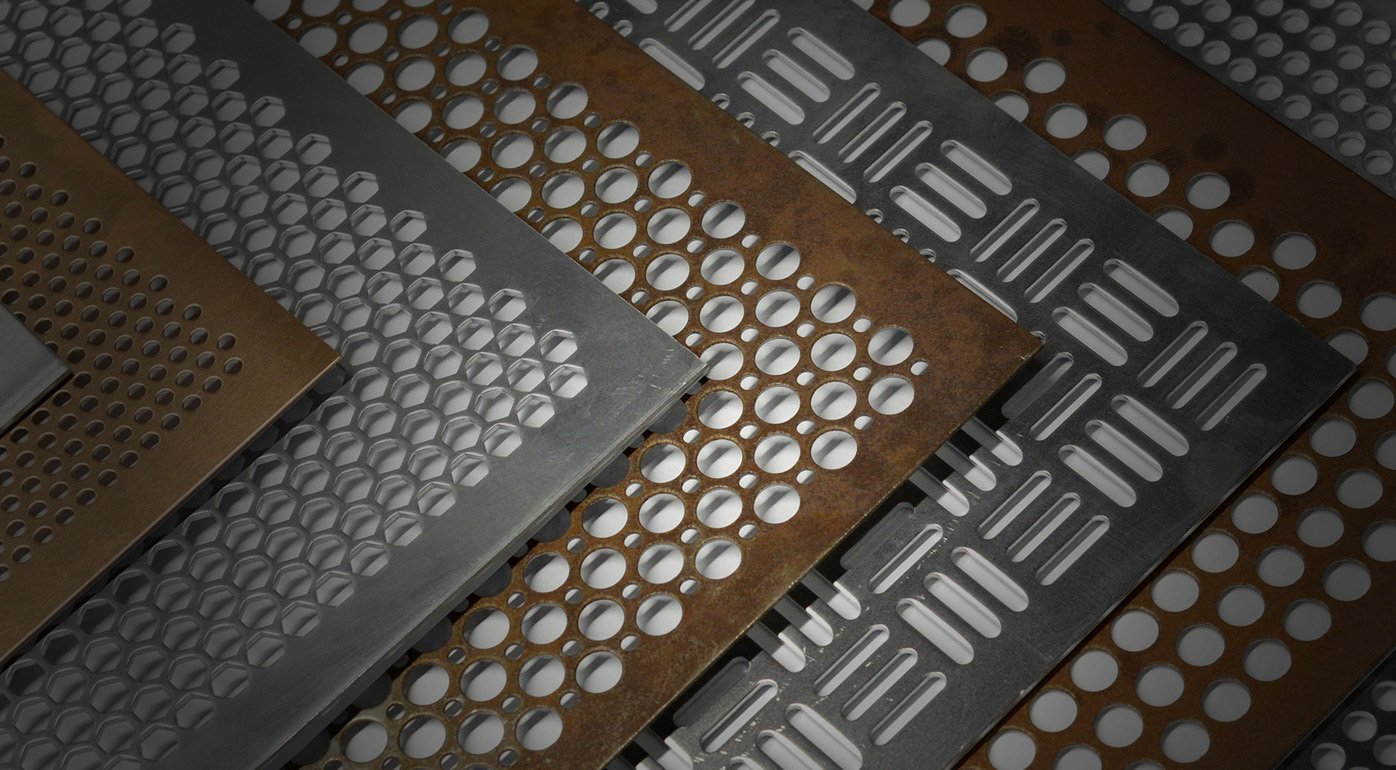

Whether you call it a diamond or a checker plate; it’s actually a type of metal stock which comes with a regular pattern of raised diamonds or lines on one side, with the reverse side being featureless. It is made of aluminum or stainless steel.

The diamond plate made of aluminum is the best choice when it comes to looking for a product with a combination of strong durability and exterior looks.

This product is widely used in stairs, ramps, industrial walkways, kick plates and in all those applications where the material is subjected to elements of daily wear and tear.

Let’s talk about its level of thickness to use this product for trailer flooring. It’s very important to choose an accurate level of thickness for product safety.

Trailer flooring has to be durable, and an anti-slip reliable. Using aluminum diamond plates, you can get the perfect balance of durability and aesthetics.

What thickness should I use for flooring?

The standard level of thickness should be 3/4″ of some kind of wood. If you do you do have that, at that point we prescribe running with 0.045″ or 0.063″ (1/16″).

The more structure and bolster you have on the base, the more slender you can go. 0.045″ would be the most slender we prescribe.

If you don’t have a solid help on the base or you have bars, at that point you ought to go thicker. The most prevalent thicknesses would be 0.188″ (3/16″) or 0.125″ (1/8″), and even 0.25 (1/4″).

Hence, we see it all depends upon the ground surface you put down previously. Continuously mull over that while deciding the thickness you require. The thicker the help, the more slender you can go.

How to install it?

The installing procedure also depends upon the thickness of the diamond plate, and support under it, this determines how long your fasteners will be. Anyhow, you’ll the following tools for installing diamond plate for trail flooring;

- Impact Drill

- Self-tapping tin screws

First, screw along the edge of sheets. One more thing you can do is, screw down the central part of sheets to protect it from rattling, and for better security.

If there are two sheets meeting together, then don’t forget to screw the edges of both sheets.

Where Do I Buy Aluminum Diamond Plate?

If you’re looking for some best diamond sheet manufacturers, then look for one who could provide you hot-rolled sheets, this feature makes the plate for fabrication. They also provide sheets in customized sizes for all parts of a trailer ranging from stone guards and flooring to wall wainscoting.

The Notable features of diamond plate sheet

Following are the best features to use diamond plate sheet for industrial and automotive purposes;

- The diamond sheets are easy to work with, also enable users to practice DIY tricks on it

- Offers easy installation

- The material can be cut with tin cuts for little employment, such as removing an electrical attachment or utilize an 18 ga hand shear to get decent perfect long queues.

Stay tuned to Xiaaluplate for a ton of interesting articles, blogs , news and updates.