Regardless of the complex diamond pattern, the process for creating a diamond plate is moderately simple. Once making a standard plate or sheet, the manufacturers bring the material through a series of large rollers until they get desired thickness. However, there is one key difference while making an aluminum tread plate. On the ultimate set of rollers, one of the plate rollers has a pattern that engraves the diamond shape onto the aluminum plate. If you look at the most aluminum diamond plate, you may notice that only one side of its characteristics the diamond pattern. It is because only a single roller in the set has an aluminum diamond-shaped design, so one side of the aluminum metal is visible while the other side is smooth.

For the aluminum Diamond tread plate, the process of “stamps” the pattern onto the aluminum plate, while with steel, the manufacturer generally uses hot rolling. The process involves heating a steel slab above its recrystallization temperature, bringing it through a series of smooth rollers to its wanted thickness. Heating the aluminum above its recrystallization temperature helps avoid significant alterations in mechanical properties because of work hardening. When the material has reached its final shape, you allow it to cool slowly.

Aluminum tread plate suppliers also mention other techniques to create aluminum diamond plates; the rolling method is most familiar. The only significant difference between a rolling plate and the diamond plate is the roller manufacturer used. It makes the process very economical. It is why you can find aluminum diamond plates often at relatively affordable prices compared with a standard plate of the same metal and dimensions.

Common Uses Of Aluminum Diamond Plates

You may most often see aluminum diamond plate used in safety applications as the pattern creates an excellent tread which can help decrease slips and falls. Generally, it is a good safety practice to use aluminum diamond plates any time people will be regularly walking over a slick metal surface. For good quality and durable material, always contact leading aluminum tread plate suppliers.

- Stairs and Walkways: you can use a Diamond plate commonly on stairs or ramps in industrial areas, which reduces the chance of slipping on the aluminum. Outdoor fire exits in exacting rely on a diamond tread plate to enhance traction once the steps become slick from snow or rain.

- Vehicles and Trailers: Most people with a pick-up truck can confirm how often they are treading in and out of the truck’s bed. Thus, people can use diamond plates often as an accent on buffers, truck beds, or trailers to help decrease skids while stepping onto a vehicle and provide traction for pulling or pushing metal on and off a truck.

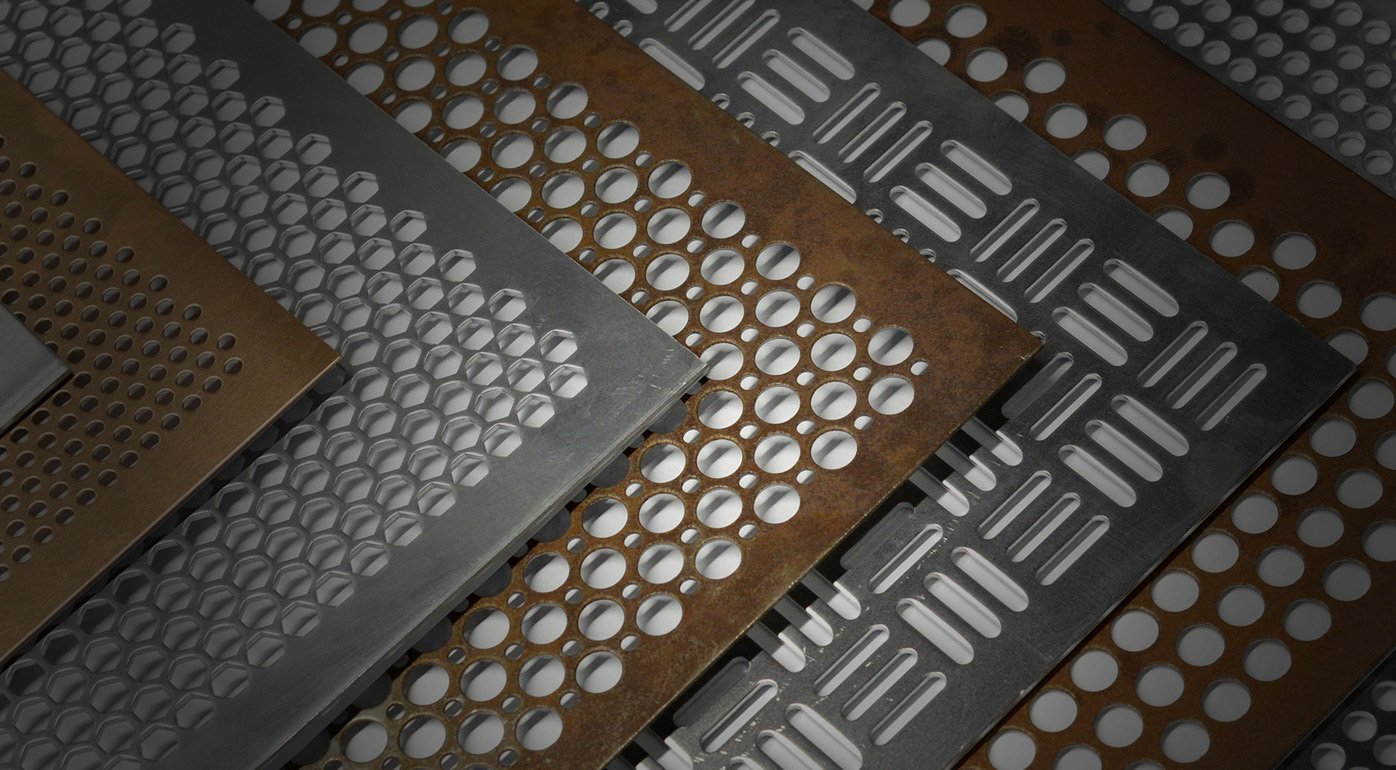

- Aesthetic Accents: Stainless steel, aluminum, and hot-rolled steel diamond tread plate each have a unique appearance and finish, which you can use as an accent for architectural elements or furniture. You can find diamond plates as runners on stairs, backsplashes, tabletops, and many more.