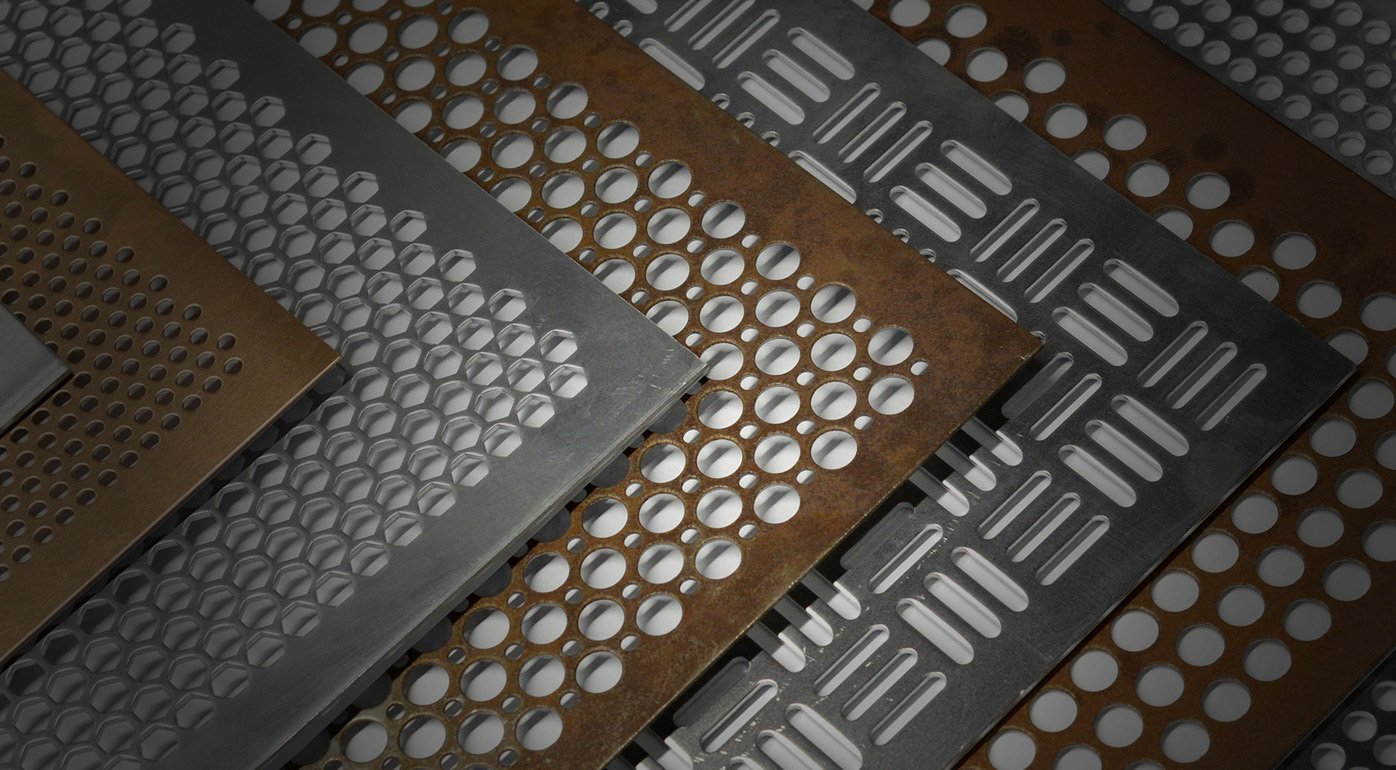

What Are Perforated Industrial Metal Sheets

It is a kind of sheet metal which is stamped or punched with a machine to make hole patterns. It is also known as a perforated plate, perforated sheet, or perforated screen and generally produced from cold rolled steel, stainless steel, aluminum and more.

The manufacturing of this product pioneered around 150 years ago as a means of filtering coal for the mining industry. The perforation process was used to be quite wasteful at that time, as it used to involve laborers who used to punch individual holes into a metal sheet.

But, the process has been improved over time with the help of using machinery for punching needles arranged in specific patterns.

How Is Perforated Metal Made?

The procedure of making perforated sheets begins with sheet metal. It is thin and flat and can be cut and bent into different shapes. The thickness of this metal is specified in gauges particularly in North America; they believe in the formula of – larger the gauge number, the thinner the metal. While in other countries, sheet metal is measured in millimeters.

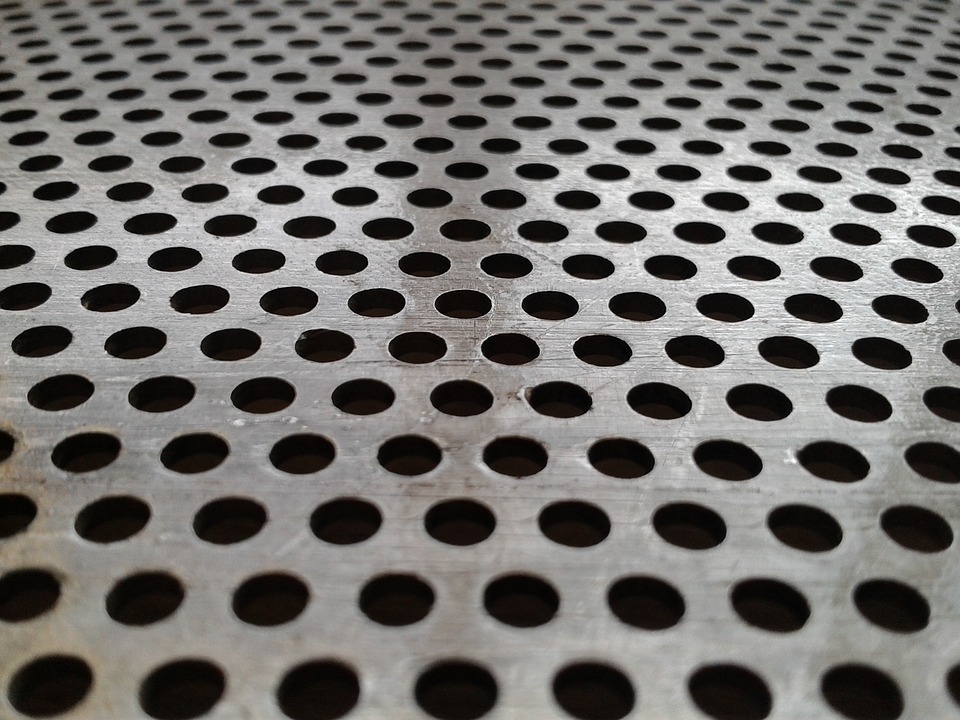

The most widely recognized technique for puncturing metal uses a rotating stuck aperture roller. This is an extensive barrel with sharp, guided needles outwardly toward punch openings into the metal.

As the sheet metal is kept running over the aperture roller, it pivots, ceaselessly punching gaps in the passing sheet.

The roller needles, which can produce a great variety of hole sizes, are heated at times to melt the metal which shapes a strengthened ring around the puncturing.

The best thing about perforated metal is, it is versatile enough to complement any structure and to add which shapes a strengthened ring around the puncturing. The perforated aluminum sheet on other hand is an excellent option for designs of all types.

Applications

Following are the few applications of perforated metals;

Sun protection and climate control

Perforated metal is best sun protection screens in rooms that require ventilation, as well as for climate control. Which shapes a fortified ring around the puncturing.

Noise reduction

Perforated metal sheets are also best for noise reduction as it can also be used in creating noise proof walls and roof systems. It can control the adverse effects of noise on workers’ health in noisy environments

Other industries that utilize perforated metals are:

Food & beverage

In terms of food and beverages, the perforated metal is used in making drain dryers, wine vats, sorting machines, fruit & vegetable presses, and baking trays.

Car

Used for oil channels, radiator grilles, running sheets, motor ventilation and cruiser silencers.

Material advancement

Used for impact heater screens, material printers and felt plants, bond slurry screens, and glass fortification.

Synthetic and vitality

Used for channels, gas purifiers, mine pens, coal washing, battery separator plates, and rotators.

Stay tuned to Xiaaluplate for more interesting blogs , updates and articles.